Dan Freeland

05.25.2021

These effective, yet simple, devices explained

How do they work?

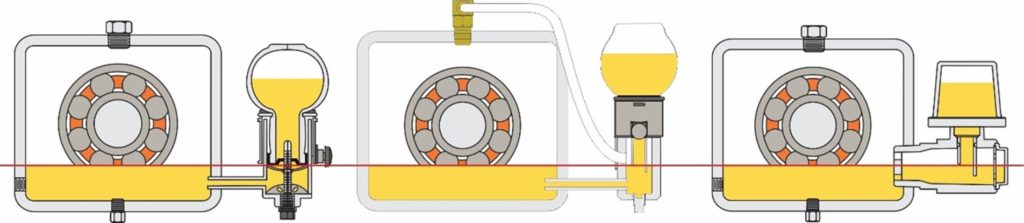

Constant level lubrication is the concept of maintaining a consistent level of oil in a lubricating sump. If there is any oil loss due to leakage or usage the reservoir of oil will provide a volume of oil. This reserve will replenish oil in the lubricating sump until the original oil level is maintained again. This will be the case if there is reserve oil in the bottle. This application has been around for many years and used by end users and original equipment manufacturers all over the world. As a result, quite often we receive inquiries about how these oilers work. The concept of a full bottle of fluid upside down, and not just emptying out, is to somehow defy logic. But, of course, this is not magic. The basic rules of fluid dynamics are at play – a function of oil displacement. The fluid in the bottle will feed out until it reaches the oil level to be maintained, based on the level adjustment mechanism. After that, if the oil breaks below the control point, regardless of which oiler, air will enter the reservoir, traveling up to where it will break in the headspace of the inverted bottle. This additional air will displace fluid out of the bottle until the path of air is no longer present, or when the control point level is re-established.

Why different types of Constant Level Oilers?

You may have wondered why you see several different types of oilers when walking through a plant? There are many reasons for choosing a particular Constant Level Oiler. Here are a couple of the most common:

- design considerations of the equipment it is on.

- contamination protection of the oil.

- equipment and ancillary products are following industry standards.

- that is the way it has been for years, and no one is going to change it.

The main thing to understand about any constant level oiler is that they all do exactly what the name implies. It does not matter which oiler you choose; they will all provide a constant level.

Throughout the years, Trico has led the reform and refinement of constant level oilers, resulting in a family of products.

- The Original Opto-Matic – The most common in industry and the one that started it all.

- The Plastic Opto-Matic – Different materials for different industries.

- The Closed System Oiler – Designed for contamination protection. Closed to outside atmosphere.

- The Watchdog Oiler – Non-adjustable – Installed directly on the centerline of the oil to be maintained.

- Sensei Enabled Opto-Matic Oiler – Trico’s latest innovation in Constant Level Lubrication. Cloud-based oiler monitoring.

Enhancing Oil Level Monitoring with Machine Vitals

Machine Vitals™ offers a powerful complement to constant level oilers by providing early indications of potential issues related to low or high oil levels. As part of the Sensei® IIoT Network, this advanced condition monitoring device tracks critical parameters such as temperature, pressure, relative humidity, acoustics, and acceleratory variance. By delivering a comprehensive overview of machinery health, Machine Vitals™ ensures that you can address oil level concerns promptly and maintain optimal equipment performance.

To learn more about all the Trico Constant level oilers, check out our latest video.

- Category:

- Application

- Contamination