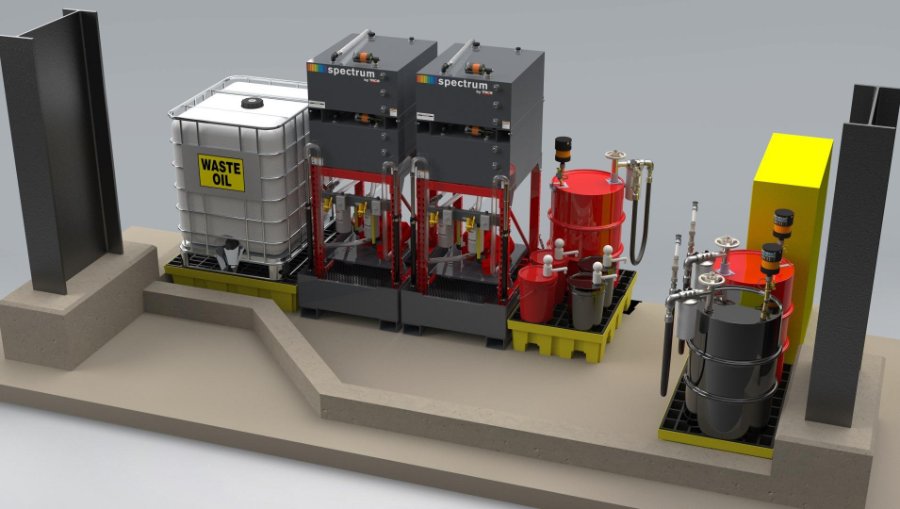

Lubricant health is essential to extending the life of machinery, and proper lubricant storage and handling is critical to maintaining a clean and healthy fluid. Many things can happen to the lubricant between bulk delivery and application. Designing a lube room is one of the first steps in achieving lubrication best practices. Implementing an industry recognized best practices lube room will extend the life of your equipment by reducing contamination that is created as a result of improper storage practices.

Our reliability consultants can work with you in designing and implementing a word class lube room or taking an existing lube room and transition it to world class status. Our hands-on consultants will work with you to enhance or create your lube room to world class status. Our services specialize in building and supporting world class lubrication programs aimed at equipment reliability and a lube room is the cornerstone of your plan.

WHEN DESIGNING A NEW LUBE ROOM OR ENHANCING AN EXISTING ONE, WE WILL:

- Investigate the logistics and space constraints

- Assess the environment and surrounding area

- Outline safety protocol

- Determine oils that need to be filtered, dispensed and stored

- Determine the appropriate dispensing equipment needed

- Set-up lubricant identification with labeling and color coding

- Outline lubricant disposal

- Discuss any other customer requirements of the lube room