Dan Freeland

01.21.2025

How Machine Vitals and Sensei Platform Bring Solutions to Challenges Highlighted by Frost & Sullivan

While browsing online, I came across an article about a survey by Frost & Sullivan that caught my attention. It felt very relevant to some of the recent posts we’ve shared on Lubricology about Machine Vitals. Like many industries, the pulp and paper sector is undergoing major changes. Frost & Sullivan’s executive brief, Pulp and Paper in the Digital Era, provides a timely perspective on how digital solutions are driving this transformation.Challenges like rising costs, labor shortages, and stricter sustainability requirements might seem overwhelming, but they also present a unique opportunity for the industry to leverage technology for impactful results.

Frost & Sullivan’s insights really emphasize the value of solutions like Machine Vitals, the Sensei Web Platform, the Mobile App, and the Sensei Enabled Opto-Matic Oiler. This is a great opportunity to evaluate how our solutions align with the evolving needs of the pulp and paper industry (and others) while highlighting some key findings from the research.

Digital Challenges in Pulp and Paper: Where the Numbers Speak

Frost & Sullivan surveyed executives and operations managers across the globe, revealing striking truths about the current state of the pulp and paper sector:

Downtime Drains the Bottom Line

Planned downtime costs companies between $30,000 and $50,000 per hour, while unplanned downtime soars to $80,000 to $150,000 per hour. Reducing these disruptions is critical to maintaining profitability and operational efficiency.

Real-Time Visibility is Limited

Nearly 50% of respondents identified the lack of real-time condition information as a key challenge, yet most organizations have not fully committed to upgrading their existing condition monitoring systems.

The Workforce Conundrum

Skill gaps and a shortage of workers were noted as significant hurdles. Even with the latest technology, inadequate training and adoption remain barriers to realizing full potential.

Bridging the Gap: How Machine Vitals and the Sensei Platform Align

Frost & Sullivan’s insights paint a clear picture of where industries like pulp and paper are struggling and where Trico’s solutions support these initiatives.

Condition Monitoring: From Reactive to Proactive

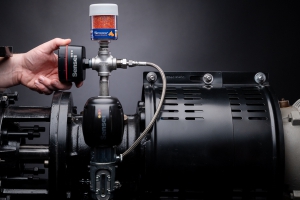

The report emphasizes that condition monitoring (CM) is widespread but underutilized, with outdated systems failing to meet modern needs. Machine Vitals: our advanced sensor platform is designed to provide real-time visibility into equipment health. By continuously monitoring parameters such as vibration, temperature, humidity, and pressure, Machine Vitals detects issues before they escalate into costly unplanned downtime.

Predictive Maintenance: The Data-Driven Approach

Predictive maintenance was highlighted in the report as a turning point for reducing downtime. The Sensei web-based dashboard takes CM data from Machine Vitals and integrates it into a cloud-based analytics engine, enabling maintenance teams to predict and prioritize repairs. Frost & Sullivan’s research backs this up, noting how advanced analytics and AI can increase asset reliability, lifespan, and efficiency.

Sustainability Meets Practicality

One standout statistic: The pulp and paper industry spends 40% of its energy budget on renewable and alternative fuels. Sustainability goals, such as reducing water consumption and emissions, are more attainable when equipment operates at peak performance. By providing early warnings of inefficiencies, Machine Vitals directly supports initiatives to reduce energy waste and carbon footprints.

The Human Element: Insights from Industry Leaders

Frost & Sullivan didn’t just crunch numbers, they captured the voices of industry experts:

- A German general manager cited the importance of bridging skill gaps and adopting cutting-edge tools to stay competitive.

- A Nordic region manager highlighted the shift toward predictive analytics as a pivotal strategy for reducing downtime.

- A US based executive described the challenge of balancing technological complexity with workforce training, underscoring the need for intuitive, user-friendly solutions.

Building Momentum: The Path Forward

The Frost & Sullivan report concludes with a call to action for the pulp and paper industry to modernize, scale, and integrate digital solutions effectively. At Trico, we share this vision, offering tools and platforms that deliver real-time insights, foster predictive maintenance, and drive measurable ROI.Scalability has been a priority for Trico from the start. We understand that no one wants to jump into something new and untested without first seeing how it works in their specific setup. That’s why we focus on taking small, manageable steps before scaling up.

We offer custom pilot programs designed to fit each customer’s unique needs. These programs let you test the system in a real-world environment and see the results firsthand. Once you’re confident in how it performs and the value it provides, expanding gradually becomes a natural next step.

The toughest part for most customers is overcoming that initial uncertainty of trying something new. Our tailored approach helps you ease into the process, making it simple to build trust in the technology and move forward at a pace that works for you.

Solutions like Machine Vitals, Sensei Web Platform, the Mobile App and the Sensei Enabled Opto-Matic Oiler help companies go beyond just fixing surface-level problems. They tackle the root causes of inefficiencies. By addressing these deeper issues, businesses can turn challenges, like the ones highlighted in Frost & Sullivan’s research, into opportunities for growth, doing more with less, and long-term unplanned downtime reduction.

Partnering for Progress

The digital revolution isn’t about reinventing the wheel, it’s about making it spin smoother, faster, and more efficiently. As the pulp and paper industry navigates its own transformation, Trico stands ready to provide the tools, expertise, and support needed to thrive.The future is clear: those who embrace digital solutions will lead the way, proving that with the right data and insights, even the oldest industries can write a new chapter.

Are you ready to start a pilot program?

Are you ready to start a pilot program?

A pilot program with Machine Vitals is your key to unlocking real-time insights, reducing downtime, and staying ahead of potential issues. Contact us today to start your journey toward a more proactive approach to equipment health. Let’s make your operations more reliable together.References:

Frost & Sullivan, Pulp and Paper in the Digital Era (2023). Courtesy of: Augury Inc.