Dan Freeland

03.04.2025

Transition from 1925 to 2025

Manual Greasing: A Time-Tested Tradition

The practice of manual greasing began with the invention of the grease gun in 1925. Many iterations and supplemental products later, it still stands as an acceptable practice. as long as it’s done right. Using the correct grease guns for pressure requirements, grease meters to measure the exact amount dispensed, and color-coding methods (grease gun collars, engraved colored tags, grease washers under zerk fittings, and colored zerk fitting caps) help prevent cross-contamination and misapplication.But, let’s be honest, why would you not want to automate this laborious and antiquated process

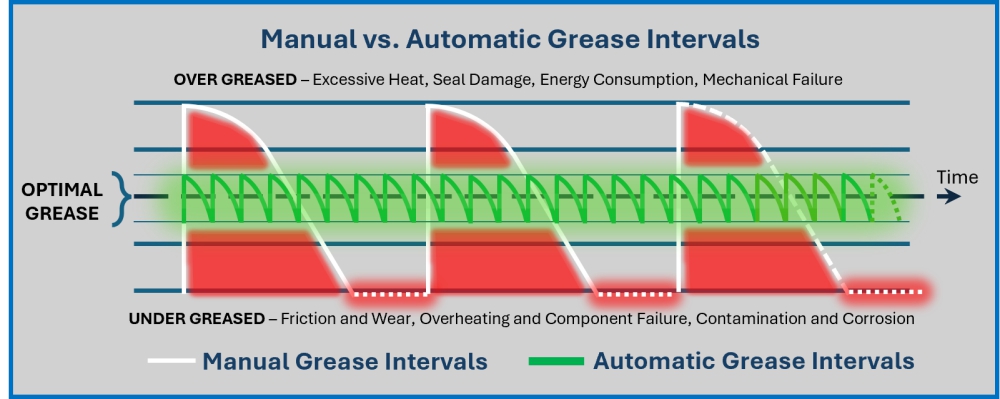

The advancement from once-a-month manual cycle (maybe) to automatic lubrication systems has modernized maintenance. Automatic grease lubricators ensure the right amount of lubricant is dispensed at the right time (Fig.1), eliminating over- and under-lubrication while saving valuable labor hours.

More Benefits of Automatic Greasing

Once installed, automatic grease lubricators eliminate the need for manual application, reducing errors and inconsistencies. Consider a facility with 200 lubrication points, each requiring manual greasing once a month. If each takes 5 minutes, that’s 16+ hours of labor every month. Automating this process frees up valuable maintenance hours while ensuring precise lubrication that extends bearing life.

Types of Automatic Grease Dispensers

The Gas-Powered Precision: DC & V Series Lubricators

For those looking for a simple, pressure-independent greasing solution, Trico’s DC and V series gas-type lubricators provide a reliable and efficient alternative.DC Series: The Set-It-and-Forget-It Solution

The DC Series is powered by a chemical reaction that generates gas pressure to push grease at a steady rate. This makes it an excellent choice for environments where fluctuating temperatures and variable pressures aren’t a concern. With multiple discharge settings available, the DC Series offers controlled lubrication over a designated period.

V Series: Versatility Meets Control

The V Series uses an adjustable gas-driven system to provide a continuous grease flow. Unlike the DC Series, the V Series can handle temperature variations more effectively, making it ideal for more demanding applications. With no external power source required, it is a simple yet effective way to ensure continuous lubrication.

The Electromechanical Powerhouses: M, Mi, and MSP Series

For applications demanding higher precision and control, Trico’s M series, Mi series, and MSP series electromechanical lubricators step up to the plate. Unlike gas-powered models, these grease dispensers use motor-driven mechanisms to deliver lubrication with pinpoint accuracy.M Series: Smart and Reliable

The M Series delivers precise, programmable lubrication using an internal motor and battery power. With multiple setting options for different grease delivery rates, it is an ideal choice for single-point lubrication where precision is crucial. Its user-friendly LCD display provides real-time monitoring of lubrication cycles, making it a dependable and efficient option for critical applications.

Mi Series: Intelligent Vibration-Based Lubrication

The Streamliner Mi Grease Dispenser is designed to detect the operation of industrial rotating machinery using a piezoelectric vibration sensor. It periodically checks the operational status of the machinery it is attached to. When the Streamliner Mi receives a vibration signal from the equipment, it dispenses grease. If no vibration signal is detected, the unit automatically enters standby mode, preventing over-lubrication and extending grease life. This makes the Mi Series ideal for applications where lubrication should only occur when the machine is running.

MSP Series: Synchronizing Lubrication with Machine Operation

The Streamliner MSP unit offers the advantage of providing automatic lubrication to machinery that is infrequently or intermittently used. By synchronizing itself to the equipment, the MSP unit avoids the common problem of over-lubrication. It dispenses a preset amount of grease only when the machine is running, ensuring optimal lubrication without waste. When the equipment stops, the MSP unit enters standby mode until the machine resumes operation. Additionally, the MSP can be externally powered by the machine or a PLC system, making it highly adaptable to different industrial environments.

The Bottom Line: Smarter Lubrication, Longer Bearing Life

Gone are the days of unreliable manual greasing and its costly aftermath. With Trico’s automatic grease lubricators, you get precision, efficiency, and peace of mind—ensuring your bearings operate smoothly without excessive downtime or maintenance headaches.So, whether you need the simplicity of gas-powered lubrication (DC & V series) or the advanced control of electromechanical systems (M, Mi, & MSP series), Trico has a solution tailored to your needs. Because when it comes to greasing bearings, it's not just about adding lubricant—it's about doing it the right way, every time.

- Category:

- Application

- Tags:

- Grease Dispensers