Dan Freeland

01.07.2025

Smarter Maintenance Starts Here

Brand names for product families and individual products can sometimes overlap, potentially leading to confusion or misunderstanding. Nearly two years ago, Trico introduced the first of several of its “Sensei-Enabled” devices, and since then, additional products have been added to expand the Sensei platform. This article aims to provide clarity about the Sensei product platform and explain the devices that drive the data, making it the most complete and unique platform for industrial lubrication, equipment monitoring, oil analysis, and trending data analysis.Before diving into the specific products that make up the Sensei platform, it’s important to first understand the infrastructure that facilitates data transfer from these devices to the cloud, enabling users to view and analyze the information on almost any electronic device like laptops.

The Sensei Gateway

The Sensei Gateway is like a bridge that connects sensors on industrial machines to the internet. Imagine you have sensors installed on machines in a factory. These sensors collect important data that can tell you if something is happening that may have a future outcome that is detrimental to the equipment. But this data needs to be sent somewhere for analysis. That’s where the Sensei Gateway comes in. It first gathers data from all those sensors. Then it translates the data into a format that can be sent over the internet. Once formatted, the gateway sends the information to the cloud, where advanced software can analyze it and alert technicians if something needs attention. At least one gateway is required for the installation of any devices.

The Sensei Gateway is like a bridge that connects sensors on industrial machines to the internet. Imagine you have sensors installed on machines in a factory. These sensors collect important data that can tell you if something is happening that may have a future outcome that is detrimental to the equipment. But this data needs to be sent somewhere for analysis. That’s where the Sensei Gateway comes in. It first gathers data from all those sensors. Then it translates the data into a format that can be sent over the internet. Once formatted, the gateway sends the information to the cloud, where advanced software can analyze it and alert technicians if something needs attention. At least one gateway is required for the installation of any devices.

The Sensei Repeater

The Sensei Repeaters are like signal boosters for industrial sensors, helping data travel longer distances without getting lost or weak. Having sensors on machines spread out across a large factory or plant, some might be too far from the Sensei Gateway or tucked away in hard-to-reach spots. Without help, their signals could be too weak to make it all the way to the gateway. These repeaters will pick up the sensor's signal and amplify it. They then send the signal forward to the gateway. Repeaters may not be required in an installation if the proximity of the Gateway is close enough to the sensors, but if distances start to reach over approximately 300ft line of sight, one or multiple repeaters can be utilized. With these Repeaters in place, sensors can communicate across large plants or facilities with lots of obstacles, ensuring no valuable data is missed.

The Sensei Repeaters are like signal boosters for industrial sensors, helping data travel longer distances without getting lost or weak. Having sensors on machines spread out across a large factory or plant, some might be too far from the Sensei Gateway or tucked away in hard-to-reach spots. Without help, their signals could be too weak to make it all the way to the gateway. These repeaters will pick up the sensor's signal and amplify it. They then send the signal forward to the gateway. Repeaters may not be required in an installation if the proximity of the Gateway is close enough to the sensors, but if distances start to reach over approximately 300ft line of sight, one or multiple repeaters can be utilized. With these Repeaters in place, sensors can communicate across large plants or facilities with lots of obstacles, ensuring no valuable data is missed.

The Sensei Web Platform

The Sensei Web Platform provides comprehensive real-time monitoring and analysis of equipment health by aggregating data from connected Sensei devices. It offers users instant access to live sensor readings, allowing them to detect issues like abnormal pressure, temperature fluctuations, or unusual vibration patterns as they occur. Historical data is also collected and analyzed to identify long-term trends, helping maintenance teams predict potential failures and schedule interventions before problems escalate. Through proprietary algorithms, the platform translates raw data into actionable insights, alerting users to potential imbalances, lubrication issues, or bearing wear. Customizable dashboards ensure that critical parameters are front and center, while automated alerts and notifications enable rapid responses to concerning conditions. For multi-site operations, the platform consolidates data across locations, providing a centralized view of equipment performance.

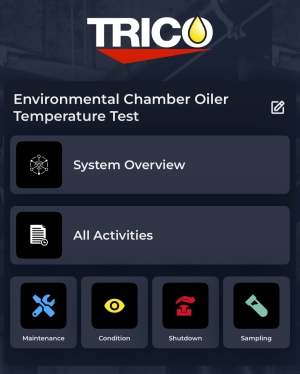

The Trico Mobile App

The Sensei Mobile App plays a critical role in streamlining manual data entry and equipment event tracking, enhancing the overall equipment monitoring process and data analysis. It allows users to log essential information such as equipment shutdowns, inspections, oil changes, and filtration activities, ensuring comprehensive documentation of maintenance activities. By enabling direct input of Equipment Data Sheet (EDS) information, the app bridges the gap between field activities and the Sensei Web Platform, keeping records up to date and accurate.

The Sensei Mobile App plays a critical role in streamlining manual data entry and equipment event tracking, enhancing the overall equipment monitoring process and data analysis. It allows users to log essential information such as equipment shutdowns, inspections, oil changes, and filtration activities, ensuring comprehensive documentation of maintenance activities. By enabling direct input of Equipment Data Sheet (EDS) information, the app bridges the gap between field activities and the Sensei Web Platform, keeping records up to date and accurate. A key feature of the app is its integrated camera function, which reads QR codes from either Trico-supplied engraved equipment tags or customer-supplied QR Codes. This simplifies the process of preparing and submitting oil samples to Trico for analysis by automatically linking the sample to the correct SPID (Sample Point ID) in Orbital, Trico’s oil analysis software. Once the sample is processed, high-level results are posted directly to the Sensei Web Platform, creating a seamless loop between condition monitoring and oil analysis. This connectivity ensures that maintenance teams have easy access to all the vital equipment health data, historical equipment events, and the latest oil analysis in one convenient, intuitive platform - contributing to more efficient decision-making and enhanced equipment reliability.

The components outlined above form the essential infrastructure of the Sensei experience. Now, let’s look at the Sensei-enabled devices and systems that can be monitored through this holistic equipment and lubrication health management monitoring system.

The Sensei Opto-Matic Oiler

The Sensei Opto-Matic Oiler is like a virtual oil level indicator, specifically designed to monitor oil levels in the familiar Trico constant level oilers in real-time. Much like when doing a lube route, maintenance technicians check to make sure there is oil in the glass bulb, but now every oiler’s oil level in your plant can be seen at once, on one screen. This type of information is invaluable when sending out personnel to do top-offs or inspections. Priorities can be decided quickly as to which equipment to check, instead of a time-consuming stroll that has maintenance techs wandering throughout the plant for hours, sometimes days, at a time.

The Sensei Opto-Matic Oiler is like a virtual oil level indicator, specifically designed to monitor oil levels in the familiar Trico constant level oilers in real-time. Much like when doing a lube route, maintenance technicians check to make sure there is oil in the glass bulb, but now every oiler’s oil level in your plant can be seen at once, on one screen. This type of information is invaluable when sending out personnel to do top-offs or inspections. Priorities can be decided quickly as to which equipment to check, instead of a time-consuming stroll that has maintenance techs wandering throughout the plant for hours, sometimes days, at a time. The Sensei Opto-Matic Oiler can also track top-off history, equipment oil consumption, and present repeat offenders that often require scheduled maintenance to fix the issue. These oilers are retrofittable to existing Opto-Matic Oiler installations (closed systems or vented), meaning you can leave the lower assembly of the oiler mounted in its current location and replace only the upper reservoir assembly. These oilers are also rated for hazardous locations.

Spectrum Bulk Storage Intelligent System

The Spectrum Bulk Storage Intelligent System is like a smart assistant for managing 55-gallon tanks of oil and other fluid industrial lubricants. It helps factories and plants track, control, and optimize their bulk lubricant inventory, so they never run out or waste supplies. It is a clean and organized way of storing your large-volume lubricants. Along with having a digital display for the operation of dispensing, filling, and filtering, the Intelligent System monitors stored lubricant levels in real time using the same Sensei infrastructure. The system can automatically generate alerts when the re-order point is reached and how much oil is remaining. It can also quantify oil consumption on bulk usage.

The Spectrum Bulk Storage Intelligent System is like a smart assistant for managing 55-gallon tanks of oil and other fluid industrial lubricants. It helps factories and plants track, control, and optimize their bulk lubricant inventory, so they never run out or waste supplies. It is a clean and organized way of storing your large-volume lubricants. Along with having a digital display for the operation of dispensing, filling, and filtering, the Intelligent System monitors stored lubricant levels in real time using the same Sensei infrastructure. The system can automatically generate alerts when the re-order point is reached and how much oil is remaining. It can also quantify oil consumption on bulk usage.

Machine Vitals

Threading a Machine Vitals device into the headspace above the lubricating oil in pumps, gearboxes, hydraulic tanks, and other equipment is like strapping on a fitness tracker to your industrial machines, giving you a constant check-up on their health by monitoring vibration, temperature, pressure, and humidity. Much like commercial watches and devices that are available for humans, it’s designed to monitor specific parameters, catching anomalies and potential problems early – before they lead to serious health conditions. If you think about it, whether you are doing a physical manual inspection or utilizing oil analysis, each is simply a snapshot of time. Much like your annual doctor visit or blood work, each are a snapshot of the condition at that specific time.

Well, what about the rest of the time? People buy these fitness trackers to monitor their specific parameters 24/7 to alert them when something is not right or, even better, everything is alright. Machine Vitals is that fitness tracker for your equipment that monitors 24/7, providing valuable parameter data that can alert you when something just isn’t right, or everything is running just fine. There is no longer a reason to have to wait for annual or semiannual “checkups” to hope all is good. This is daily peace of mind.

Vibration sensors detect imbalance, misalignment, or bearing wear. Temperature and pressure sensors monitor oil conditions and machine heat. Internal and external humidity sensors check for moisture that could lead to corrosion or contamination. Acoustic monitoring listens for unusual noises that could signal internal problems. All in this compact, spin-on, equipment health tracker.

Summing up the Sensei Platform

The Sensei platform isn’t just another monitoring system – it’s like having a team of tireless, watchful technicians keeping an eye on your equipment 24/7, minus the coffee breaks. From real-time oil level monitoring to vibration analysis and bulk storage management, Sensei-enabled devices work together seamlessly to provide a complete view of your plant’s health. It’s a smarter, more connected way to keep operations running smoothly, reduce downtime, and prioritize maintenance where it truly matters. By leveraging the power of data and automation, Sensei transforms how maintenance teams operate, helping them move from reactive “fix-it-when-it-breaks” modes to proactive, predictive strategies. Whether it’s keeping tabs on oil levels, monitoring machine health, or streamlining oil analysis, the Sensei platform simplifies complex processes and delivers the insights you need – when you need them. It’s like giving your equipment a personal trainer, doctor, and security system all in one compact package. Whether you start with one device or multiple, the more you use, the clearer the overall picture becomes.

Are Your Ready?

So, if you’re ready to step into the future of industrial equipment monitoring (and maybe free up some time for that well-earned coffee break), Trico’s Sensei Platform is ready, are you? Contact us to get started!- Category:

- Lubrication Program