Sensei Enabled Opto-Matic Oiler

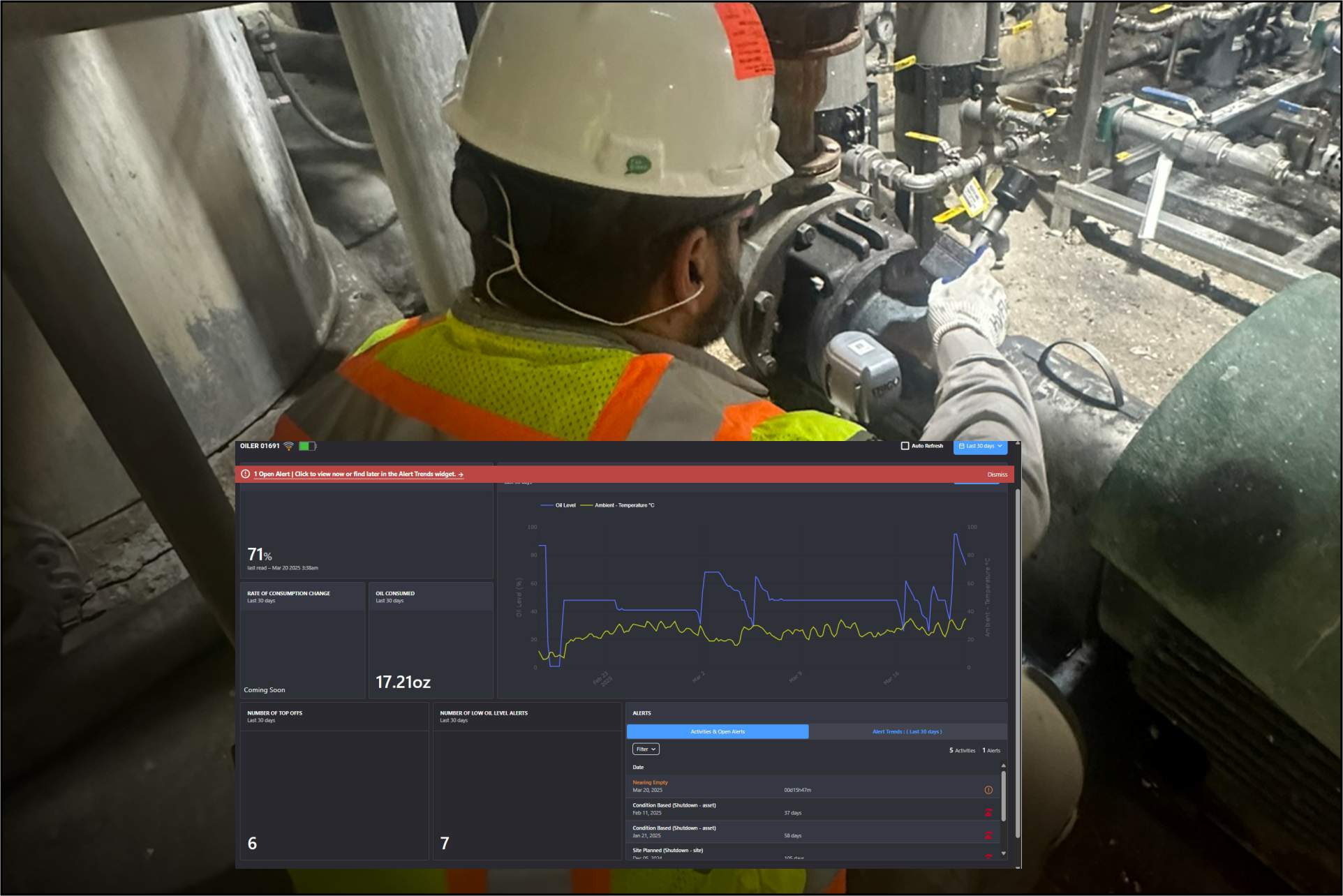

Say goodbye to traditional lube routes, unnecessary maintenance, and emergency service with Sensei® Enabled Opto-Matic Oiler, part of the Sensei IIoT Network. This innovative system allows you to keep a constant watch on the lubricant inside your equipment, enabling your team to be more proactive and efficient.

With quick installation and easy expansion capabilities, Sensei Enabled Opto-Matic Oiler provides everything you need to swiftly identify, solve, and optimize lubrication issues, ensuring uninterrupted equipment operation. Don't wait for problems to arise – let Sensei Enabled Opto-Matic Oiler empowers you to maintain peak performance effortlessly.

Feature

Anywhere Oil Level Monitoring

Remote monitoring of oil levels in critical equipment is a game-changer. By detecting potential issues or leaks early on, you can take immediate action and avoid unexpected disruptions. Plan maintenance activities effectively and make informed decisions based on accurate data.

Sensei Enabled Opto-Matic Enabled Oiler gives you peace of mind, knowing that you can access oil level data anytime, anywhere. Take control of your equipment's maintenance needs, reduce operational risks, and maximize profitability.

Feature

Problematic Equipment

By taking timely corrective action based on these alerts, companies can prevent serious incidents from occurring. Through the implementation of Sensei Enabled Opto-Matic Oiler, companies can safeguard the well-being of their workforce, minimize costly downtime, and enhance overall operational efficiency.

Sensei Platform

Empowering Data-Driven Decision Making

Platform Overview

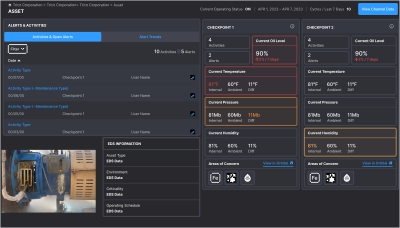

Monitor

Monitors oil level and ambient temperature and translates the data into simple visual formats.

Manage

Easily identify any issues to achieve optimal equipment performance.

Act

Provides the necessary data needed to plan and prioritize maintenance activities instead of being reactive.

Permissions

Supports numerous user types with varying permissions and flexible notification policies.

Customization

Flexible entity structure allows for customizable reporting and expansion of presenting data.

Scalable

Built using HTML 5 which allows scalability on any device type, preserving the best user experience.

Alerts

Allows users to configure alert and alarm parameters and assign notification methods, including text and email.

Gain Powerful Insights

Identify Bad Actors

Trends historically problematic equipment and alerts on bad actors

Quantify Consumption

Monitors fluctuations in oil consumption due to possible unnoticed leaks.

Verify Maintenance Top Offs and Refills

Provides real-time oil level from equipment anywhere even in hard to reach and safety concerning areas.

Days Remaining

Predicts days remaining until empty oiler to prevent low levels.

Performance Indication

Verifies lubricant is doing its job to help keep your crucial machines up and running.

Anticipate Failure Risks

Identifies potential problems before they occur.

Identifies Equipment that Needs Attention

Allows your staff to focus on high priority tasks instead of making unnecessary trips to equipment that do not need attention.

Feature

Prevent Low Oil Levels

Additional Features

- Lubricant Monitoring

- Continuous infrared monitoring of oil level and ambient temperature

- Ongoing Insights

- Continuously monitors and transmits key parameters to your network

- Simple to Integrate

- Sensing devices install in minutes on your equipment

- Battery Life

- Minimum 3-year battery life. Batteries are replaceable.

- Closed System

- Prevents ingression of contaminants into the lubricant

- Sight Gauge

- Two-inch sight gauge for easy viewing of oil level. Oil level can be viewed through Sensei Platform as well.

- Reservoir

- One piece glass reservoir ensures constant level function.

- Oil Level Range

- Adjustable level setting with 0.68” range.

Other Specs

| Model | Description | Oiler Type | Intrinsically Safe | Kit Option | Capacity |

|---|---|---|---|---|---|

| 38100 | Sensei Enabled Closed System Opto-Matic Oiler | Closed System | No | No | 8 oz |

| 38101 | Sensei Enabled Vented Opto-Matic Oiler | Vented | No | No | 8 oz |

| 38110 | Sensei Enabled Closed System Opto-Matic Oiler, with Expansion Chamber and Braided Line | Closed System | No | Yes | 8 oz |

| 38120 | Sensei Enabled Closed System Opto-Matic Oiler, Instrinsically Safe | Closed System | Yes | No | 8 oz |

| 38121 | Sensei Enabled Vented Opto-Matic Oiler, Intrinsically Safe | Vented | Yes | No | 8 oz |

| 38130 | Sensei Enabled Closed System Opto-Matic Oiler, with EX Breather and Braided Line | Closed System | Yes | Yes | 8 oz |

-

Dimensions5” x 3.25” 4”

-

MaterialHousing PC/ABS, Seal: TPE

-

IntegrationSensor Mounted to #5 (8 oz) Opto-Matic Closed System Oiler or Vented Opto-Matic Oiler

-

Oil Level Measurements1/8” Increments

-

Wireless2.4 GHz – Low power network based on 802.15.4

-

Wireless Range100 m Indoor Line of Sight

-

ProtocolsMQTT

-

LEDProvides feedback on connection to network

-

InstallationIndoor or Outdoor (Ingress Protection – IP65)

-

Operating Temperature-4° to 122°F (-20° to 50°C)

-

Wireless SecurityDevice Authentication

AES-128 Encrypted Network Joining Scheme

Pre-Shared Key and Rotating Session Key

AES-128 Encrypted Secured Data Transmission

-

ETL CertificationClass I, Zone 0, AEx ia IIC T4 Ga

Class I, Division I, Groups A, B, C, D T4

Ex ia IIC T4 Ga | -20°C ≤ Ta ≤ 50°C -

IECEx CertificationEx ia IIC T4 Ga | -20°C ≤ Ta ≤ 50°C

-

ATEX CertificationEx II 1G Ex ia IIC T4 Ga | -20°C ≤ Ta ≤ 50°C

-

UKEX CertificationEx II 1G Ex ia IIC T4 Ga | -20°C ≤ Ta ≤ 50°C