Spectrum Bulk Oil Storage System - Intelligent Stack

The Intelligent Stack provides best practices in storage and dispensing and has an HMI touch panel for functionality and usability.

The system is designed to easily and effectively identify, store, handle, and dispense lubricants. It is an economical way to save space on a plant floor, while keeping lubricants organized and contaminant free. The 65-gallon tank capacity eliminates the cost of wasted space, time, labor, and unnecessary equipment purchases required when using 55-gallon drums.

Feature

Contamination Control

The Intelligent Stack provides best practices in contamination control. Each tank has inline and kidney loop filtration, an individual pump, separate lubricant lines, and stainless-steel wands. This will prevent cross-contamination between different lubricants by having completely independent set ups for each storage tank. The inline and kidney loop filtration reduces the concentration of contaminants from the oils as they are being stored before use. The filtration for each tank has pre and post filter sampling ports for oil sampling.

Feature

Sensei Enabled

The Intelligent Stack is Sensei Enabled allowing you to connect to the Sensei Platform via the Internet to remotely monitor system condition and volumetric data. The Sensei Enabled features provides monitoring of current oil level, oil consumption, low level, remaining filter life, last filter change, last kidney loop, inlet and outlet pressure, and pressure differential all remotely.

Special Feature

Full Color HMI Touch Screen

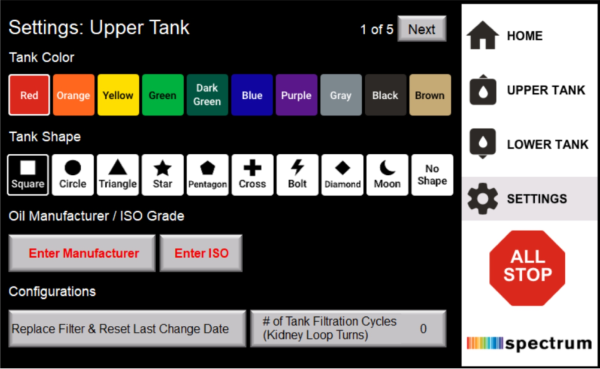

Settings Screen

Tank Identification

Select tank color as part of visual lubrication management system to ensure the right lubricant goes into the right transfer container and the right equipment.

Shape Identification

Optional selection of lubricant shape to identify tank contents for those who cannot distinguish between colors or shape can be used as secondary identifier as part of a visual lubrication management system.

Viscosity Selection

Identify contents of each tank with lubricant type and ISO viscosity grade.

Kidney Loop Set-Up

Configure the number of kidney loops for each tank.

Filter Replacement

Reset last filter change for each tank.

Lock Out

Screen lock to prevent changes to system settings.

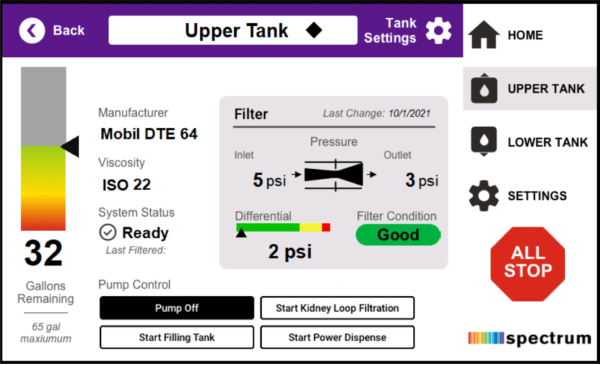

Tank Screen

Lubricant Identification

Displays the tank color and optional shape identifier for each lubricant along with description and viscosity.

Filter Condition

Indication of filter condition with the following statuses - good, order, and replace. Plus, the date of last filter change and the pressure differential for each filter.

Pump Control

Change pump status to off, kidney loop, tank filling, and power dispense mode.

Last Filtration

Identifies when the last filtration of the lubricant occurred.

Lubricant Volume

Indicates the remaining volume of lubricant in gallons for each tank.

Feature

Integrated Forklift Pockets

Performance Stack System comes with built in lift points for easy forklift and hand pallet transportation.

Additional Features

- Self-Closing Brass Dispensing Valves

These heavy-duty self-closing valves make dispensing oil quick, easy, and spill-free. The valves include 3/4" NPT threaded openings.

- 65 Gallon Tanks

10 gallons of additional capacity allows you to pump all product out of a 55-gallon drum and into the Spectrum Bulk Oil Storage tank.

- Expandable System

Easily add extra tanks with additional stack systems.

- Oil Sampling Ports

Oil sampling ports included pre and post filter

- Heavy Gauge Racking

The heavy gauge racking supports tanks when completely filled with lubricant.

- Spill Containment and Dispensing Area

Heavy duty steel constructed and built to exceed regulations of 110% capacity

- Desiccant Breathers

Prevents moisture and particulate contamination from entering tanks

- Sight Ports

Provides quick easy indication of oil level

- Shut-Off Ball Valves

Each tank is equipped with its own valve to shut-off the oil flow.

- Stainless Steel Wands

These heavy-duty stainless-steel wands are corrosion resistant to provide long life and are used to fill tanks.

- Pump Control Switch

Customer-mounted on/off switch to control the operation of the pump

- Bronze Gear Pump

Self-priming pump saves time

- Pressure Relief Valve

Prevents over pressurizing and damage to tanks

- Color-Coded Organization

Eliminate the potential for mess and mishandling by keeping each fluid clearly identified with Trico's color-coded tags and labels, part of the Spectrum Visual Lubrication Management line of products. Each label features a space to identify the specific substance contained within each tank, ensuring the right lubricant is delivered to the right equipment every time. Systems come with a set of 10 color labels and tags to clearly mark tanks and valves with oil type to ensure the right product is being used at the right application.

Other Specs

| Model | Description | Pump Motor | Depth | Width | Height |

|---|---|---|---|---|---|

| 37220 | Intelligent Stack - 240V 30 Amp Pump Motor | 240V 30 Amp | 46" | 36" | 88" |

| 37259 | Intelligent Stack - 50Hz Pump Motor | 50 Hz | 46" | 36" | 88" |

-

Tank Size65 Gallons

-

Tank MaterialPowder Coated Steel

-

Frame MaterialPowder Coated Steel

-

Oil Level IndicationsDigital Indication and Viewports

-

Oil Type IndicatorDigital Indicator and Color-Coded Labels and Tags

-

FiltrationInline and Kidney Loop Filtration

-

Filter2 – 10 Micron Filters

-

Motor1.5 HP @ 1750 RPM

-

Pump Type2 – Industrial Grade Gear Pump

-

Desiccant Breather2 – Dedicated Breather for Each Tank

-

Wand2 – 1″ ID Stainless Steel Wand

-

Hoses1-1/4″ ID Heavy Wall Wire PVC

-

Spill ContainmentYes – 73 Gallons (OSHA Compliant)

-

Dispensing ValvesSelf-Closing Bronze Valves

-

Emergency StopYes

-

Power DispenseYes

-

Filter Life IndicatorPressure Differential

-

Sampling PortsPre and Post Filter

-

Maximum ViscosityISO 680 at room temperature (70ºF)

-

Power240V 30 AMP (twist lock plug) | 50 Hz option available

-

Maximum Temperature150ºF (65ºC)

-

Rack Capacity2500 lbs

-

Overall Size88″H x 36″W x 46″H

-

Dry Weight950 lbs

-

Shipping Skid Size41″ x 58″

-

Wetted Parts Material CompositionSteel – Stainless, Galvanized & Zinc; Viton; Buna; Brass; Bronze; Iron – Galvanized & Black Coated; PVC; Aluminum

-

Color-Coded Organization

Eliminate the potential for mess and mishandling by keeping each fluid clearly identified with Trico's color-coded tags and labels, part of the Spectrum Visual Lubrication Management line of products. Each label features a space to identify the specific substance contained within each tank, ensuring the right lubricant is delivered to the right equipment every time. Systems come with a set of 10 color labels and tags to clearly mark tanks and valves with oil type to ensure the right product is being used at the right application.

.jpg?width=1440&height=450&ext=.jpg)

.jpg?width=1440&height=450&ext=.jpg)