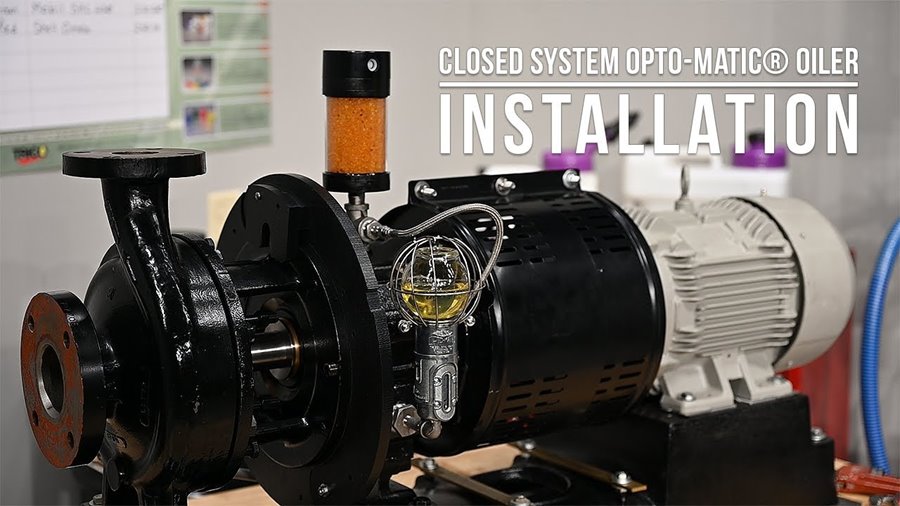

Closed System Opto-Matic Constant Level Oiler with Sight Gauge

The Closed System Opto-Matic Oiler is designed for all types of equipment where a constant level in an oil housing must be maintained. A 1/8” NPT port is provided for a vent line back to the housing to allow pressure balancing between the oiler and the housing.

Feature

Prevents Contamination

The oiler uses a pressure-balancing line to exchange air within the lubricating sump. The pressure-balancing line closes the oiler from the surrounding environment protecting the oil against contamination.

Special Feature

Three Configurations

Blue-Collar Oiler

The Blue-Collar Oiler is the original idea for a closed system oiler. The bottom edge of the blue collar represents the set oil level. The height adjustment of the oiler is possible by the slots on the two sides of the collar and kept in place by two set screws.

Zinc Die Cast Collar Oiler

The zinc die cast collar has slots on each side of the collar to allow for height adjustment and is kept in place by two set screws. It incorporates a 2-inch sight window for visual indication of the oil. However, just the like the Blue-Collar Oiler the bottom edge of the Zinc Die Cast Collar Oiler still represents where the oil level is being set to.

The Red-Collar Oiler

The Red-Collar Oiler is designed without slots, but with seven independent holes, each identified by a letter designation A through G. These holes are on both sides of the collar, offset from side to side by 1/8” increments. This allows SOP writers to identify a specific lettered hole to adjust the oiler to. The independent holes also provide a positive stop when putting the reservoir assembly back on after filling. Sometimes if the reservoir assembly is slammed onto the surge body of the slotted versions, the collar can slide down depending on how tight the set screws are.

Additional Features

- One-Piece Glass Reservoir

A one-piece glass reservoir ensures proper constant level function. Compared to competitive models, there is no possibility of leakage that would cause overfilling of the housing.

- Adjustable

Adjustable level setting allows use in many applications

- Side and Bottom Connections

Side and bottom connections for simplified installation

Other Specs

| Model | Description | Capacity | Adjustment | Sight Gauge | Dim A (in) - Width | Dim B (min) - Height | Dim B (max) - Height | Connection |

|---|---|---|---|---|---|---|---|---|

| 30103 | Closed System Oiler - Blue Collar | 4 oz | Slot | No | 2-11/16" | 7-1/16" | 7-13/16" | 1/4 NPT |

| 30105 | Closed System Oiler - Blue Collar | 8 oz | Slot | No | 3-3/16" | 8" | 8-3/4" | 1/4 NPT |

| 30110 | Closed System Oiler - Blue Collar | 16 oz | Slot | No | 4-1/8" | 8-7/8" | 9-5/8" | 1/4 NPT |

| 30203 | Closed System Oiler - Zinc Collar | 4 oz | Slot | Yes | 2-11/16" | 7-1/16" | 7-13/16" | 1/4 NPT |

| 30205 | Closed System Oiler - Zinc Collar | 8 oz | Slot | Yes | 3-3/16" | 8" | 8-3/4" | 1/4 NPT |

| 30210 | Closed System Oiler - Zinc Collar | 16 oz | Slot | Yes | 4-1/8" | 8-7/8" | 9-5/8" | 1/4 NPT |

| 40203 | Closed System Oiler - Red Collar | 4 oz | 1/8" increment holes | Yes | 2-11/16" | 7-1/16" | 7-13/16" | 1/4 NPT |

| 40205 | Closed System Oiler - Red Collar | 8 oz | 1/8" increment holes | Yes | 3-3/16" | 8" | 8-3/4" | 1/4 NPT |

| 40210 | Closed System Oiler - Red Collar | 16 oz | 1/8" increment holes | Yes | 4-1/8" | 8-7/8" | 9-5/8" | 1/4 NPT |

-

Max. Operating Temp.250ºF Continuous

-

ReservoirOne-Piece Glass Bottle

-

Upper CastingZinc

-

Lower BodyZinc

-

Adjusting CollarZinc or Anodized Aluminum

-

O-RingViton®

Smart Monitoring, Smarter Maintenance

Enhancing Oil Level Monitoring with Machine Vitals

Machine Vitals™ offers a powerful complement to constant level oilers by providing early indications of potential issues related to low or high oil levels. As part of the Sensei® IIoT Network, this advanced condition monitoring device tracks critical parameters such as temperature, pressure, relative humidity, acoustics, and acceleratory variance. By delivering a comprehensive overview of machinery health, Machine Vitals™ ensures that you can address oil level concerns promptly and maintain optimal equipment performance.

_1.jpg?width=1440&height=450&ext=.jpg)