Dan Freeland

06.18.2024

Detailed Installation Guide for the Red-Collared Opto-Matic Oiler

A while back, we introduced the concept of “Riding the Red Wave” with our red-collared closed system oilers. Since then, the red-collared closed system Opto-Matic Oiler has become the go-to choice for many of our customers, providing reliable, constant oil level maintenance.

The standout feature of the Red-Collared Opto-Matic Closed System Oiler, beyond its distinctive color, is its through-hole level setting design. Unlike the standard version with slots, the red collar’s through holes are set in 1/8” increments from side to side, labeled A-G. This design ensures a positive stop, preventing the collar from sliding and causing a lower-than-desired oil level when replacing the reservoir. The A-G designations also offer a clear reference, ensuring consistency in oil levels across all users.

We’ve received numerous inquiries for detailed installation instructions, and in response, we’ve created a short YouTube video that walks you through the installation process for the red-collar oiler.

Click here to watch the installation guide now!

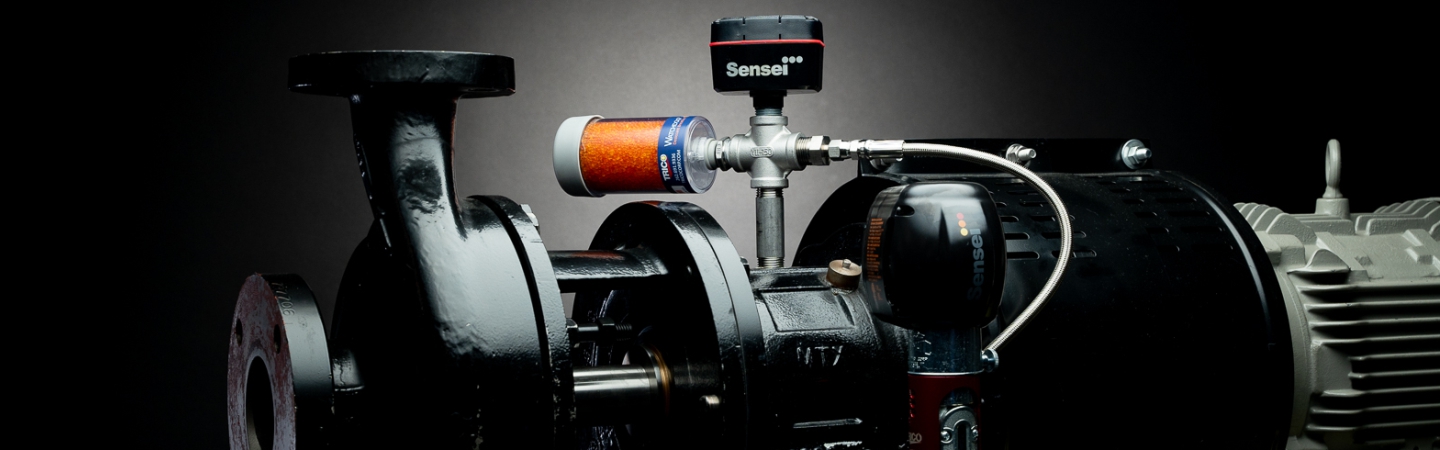

Always On – Sensei Smart Solution

Pairing the red-collar oiler with our proprietary Sensei Enabled Opto-Matic Oiler guarantees your equipment always receives the right amount of oil. With the oiler set to the correct level – continuously, you can remotely measure and monitor oil level and consumption with Sensei.

- Category:

- Application