.jpg)

Dan Freeland

11.15.2022

Accurately Set Oil Level on the Opto-Matic Oilers

The Trico Opto-Matic oiler has been, and still is, the worldwide standard in oil bath lubrication. Since the 1930’s, the same reliable product has been installed on millions of pieces of equipment in almost every industry imaginable. Even today, we are happy to field requests on how to set up and set the level of the legendary product. In this article, we’ll look at a couple of ways to effectively set your oil level on your constant level Opto-Matic Oilers.

Traditional Opto-Matic Oil Level Setting

Way back in early 2000, we created a video on the proper way to install an Opto-Matic Oiler. This video explains, step by step, how to set the level of the constant level oiler. Basically, the steps go as follows:

- Mark the outside of the bearing housing where the oil level should be.

- Pipe the lower casting so it is parallel to the oil level required and its location is within the adjustment range of the oiler. The range is 9/32”-1” from the centerline of the side port.

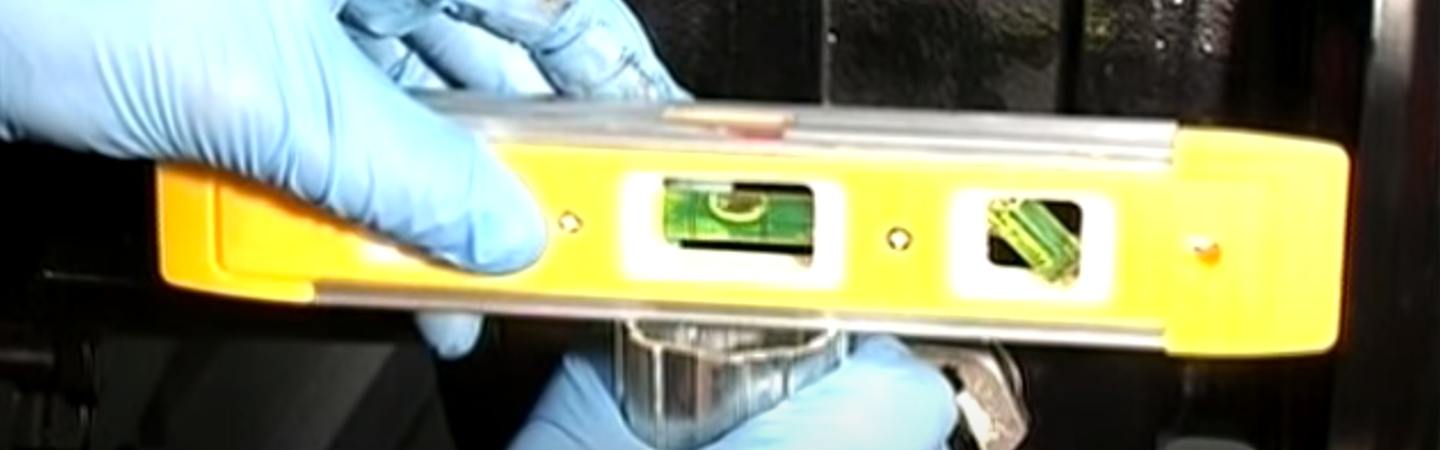

- Use a level to mark on the lower casting where the oil level should be from the marking on the equipment.

- Measure the distance from the upper casting to the end of the bottle cap.

- Put a new line on the lower casting above the oil level line the same distance as the distance “X”.

- Thread the top-level adjuster arm up to the correct oil level so the upper casting bottom edge is at the “X” line on the lower casting.

- Once that is done, lock the lower-level adjuster arm against the upper-level adjuster arm.

It may sound like a lot but when you do it once, it is relatively easy. To see how it’s done, check out the classic video here.

It may sound like a lot but when you do it once, it is relatively easy. To see how it’s done, check out the classic video here.

Advanced Laser Level Opto-Matic Oil Level Setting

In 2010, Trico designed a device to aid in the setting of the Opto-Matic Oiler. This device basically combines steps 3-6 above. Once the lower casting is piped to the proper height, the laser level can be put on to the lower casting with the level adjuster assembly inside. It uses a horizontal laser to identify the oiler level setting on your equipment. You can then turn the adjustment knob on this device to move the laser level up or down until it is in alignment with the oil level on your equipment. It is much easier that eyeballing the setting or constantly removing the reservoir to adjust the level adjusters until it is correct. This product will not only save you time, but it is also more accurate and easier to use. To see how this device works in application, click here.

In 2010, Trico designed a device to aid in the setting of the Opto-Matic Oiler. This device basically combines steps 3-6 above. Once the lower casting is piped to the proper height, the laser level can be put on to the lower casting with the level adjuster assembly inside. It uses a horizontal laser to identify the oiler level setting on your equipment. You can then turn the adjustment knob on this device to move the laser level up or down until it is in alignment with the oil level on your equipment. It is much easier that eyeballing the setting or constantly removing the reservoir to adjust the level adjusters until it is correct. This product will not only save you time, but it is also more accurate and easier to use. To see how this device works in application, click here.

Setting the Closed System Opto-Matic

Finally, last year, we did another video on installing and setting up the Closed System Opto-Matic Oiler. The Closed System Oiler includes a sight gauge to view the oil level and the bottom edge of the adjustment collar is equal to the oil level setting. Simply align the bottom edge of the collar to the line on your equipment. Verify the oil level is accurate with the sight gauge. You can see that video here.

Hopefully, this article and included links will provide you and your coworkers with the basic information to accurately set the iconic Trico Opto-Matic Oilers for many years to come. If you need additional assistance, please feel free to contact us.

Enhancing Oil Level Monitoring with Machine Vitals

Machine Vitals™ offers a powerful complement to constant level oilers by providing early indications of potential issues related to low or high oil levels. As part of the Sensei® IIoT Network, this advanced condition monitoring device tracks critical parameters such as temperature, pressure, relative humidity, acoustics, and acceleratory variance. By delivering a comprehensive overview of machinery health, Machine Vitals™ ensures that you can address oil level concerns promptly and maintain optimal equipment performance.

- Category:

- Application