What is Sensei?

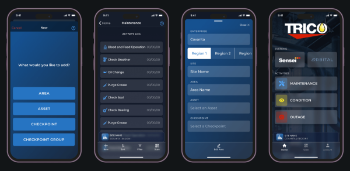

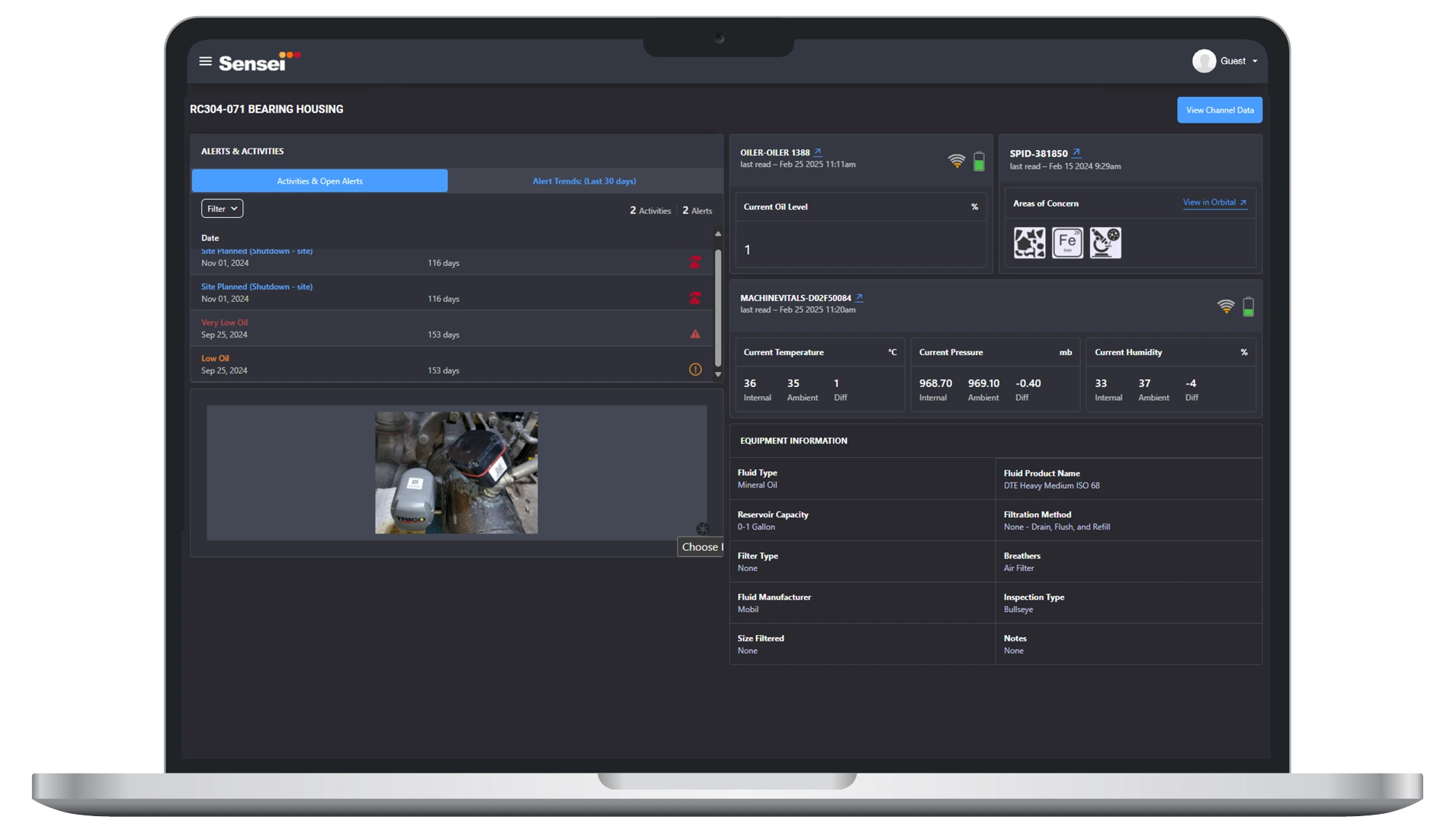

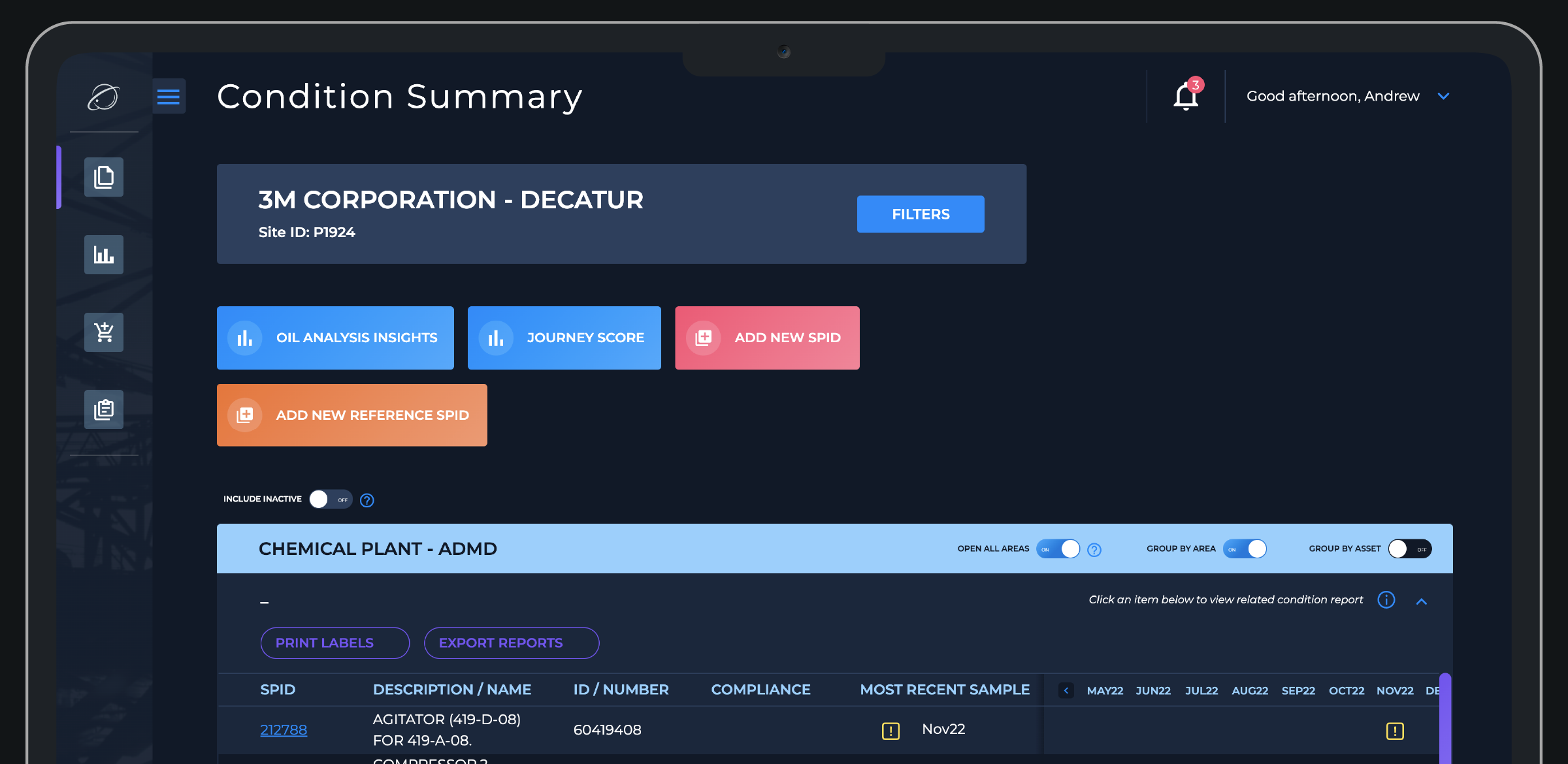

The Sensei IIoT Network uses wireless sensing devices to provide insights on equipment and lubricant conditions, enabling proactive maintenance. It consists of three components: Sensei Devices, Network Hardware, and the Sensei Platform, forming a Personal Area Network (PAN) for communication across your facility. An optional mobile app assists in adding devices to the network and assigning equipment attributes and recording maintenance activities.

Sensei Condition Monitoring System

Learn everything there is about Sensei.

Sensei Overview

What is Sensei?

Sensei Devices

Endpoint-to-Endpoint Devices

Transfer

Provides the best baseline for equipment test results. Any changes from storage to transfer is affected by personnel interactions.

Explore MoreApplication

Oil analysis offers the earliest warnings of wear and helps detect detrimental contamination.

Explore MoreLifecycle

Effective maintenance programs incorporate on-going, routine oil analysis, and data trending for continuous improvements.

Explore MoreFrequently Asked Questions

Here are some of the most frequently asked questions regarding Machine Vitals. If you have any further questions or need additional information, don't hesitate to contact us at inquiries@tricocorp.com. We are here to assist you every step of the way.

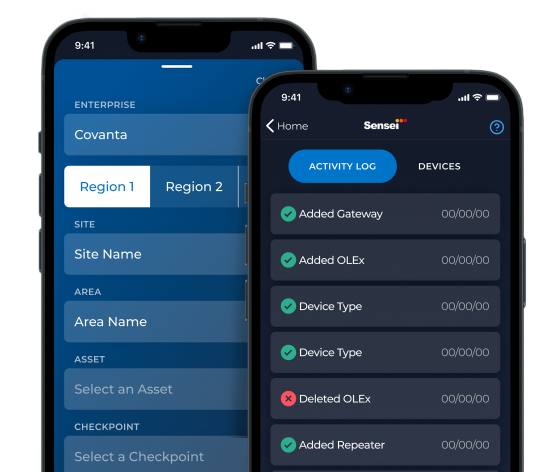

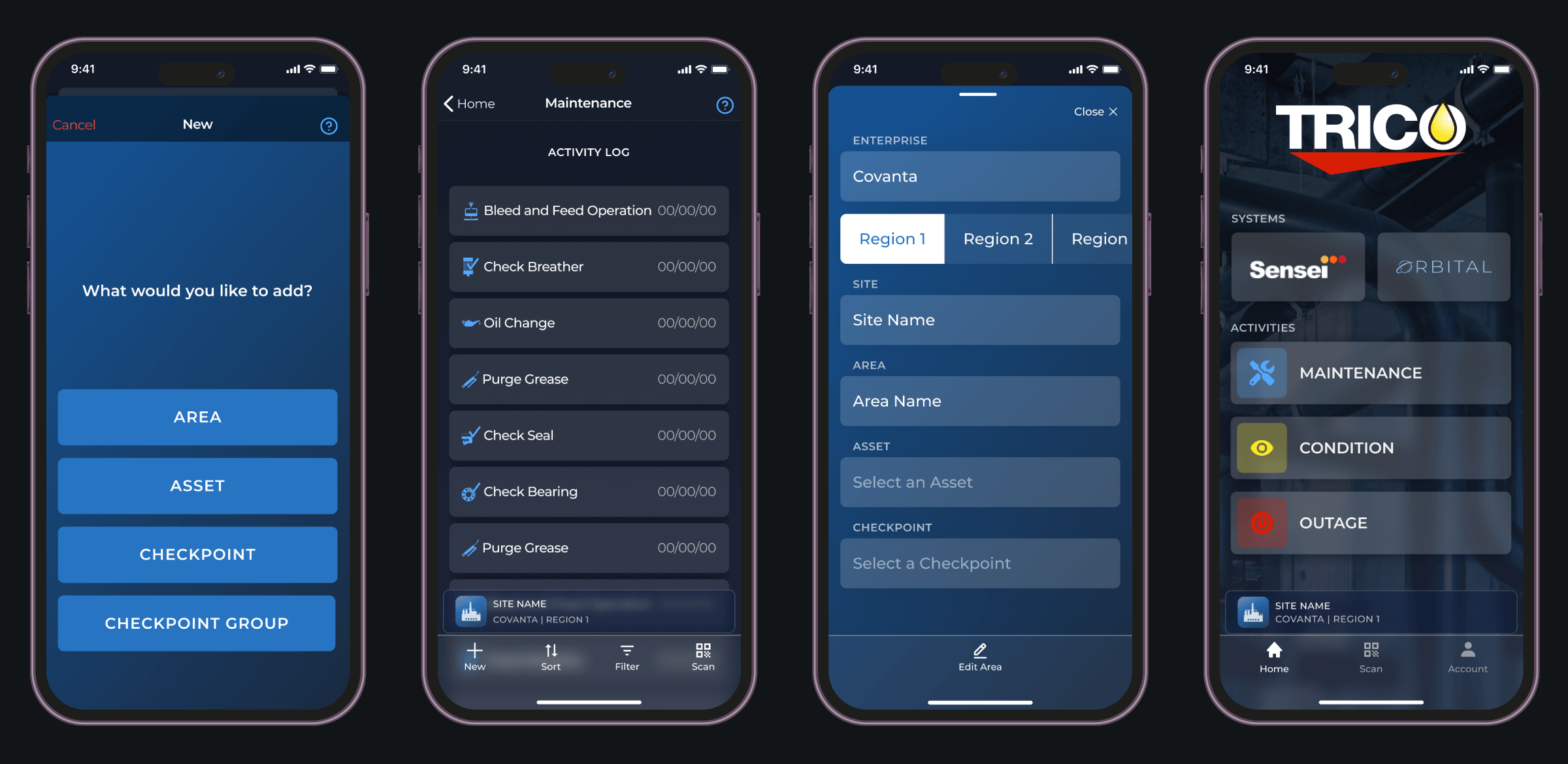

Companion Mobile App

The Maintenance Connection

Unlock the full potential of your equipment management and maintenance routines with the Trico Companion Mobile App. Designed for seamless integration with the Sensei® and Orbital® Platforms, this tool simplifies your processes, allowing you to focus on what matters most – keeping your operations running smoothly.

Lubricology Articles

Check Out Our Additional Services

Learn More From Lubricology

Services

Learn more about the services we offer by clicking on the plus sign to expand the content.

Purpose of Test The WPC, summation of DL and DS, provides a trendable quantity for monitoring the wear condition of a piece of equipment. Fluctuations in the WPC suggest an abnormal condition in the component or possible contamination.

Purpose of Test By identifying the size, shape, composition, and concentration of the abnormal wear particles, the wear mechanism and its possible origin can be determined. Solid contaminants can also be identified. Equipment and component metallurgical information aids the analyst in determining the root cause for the formation of these particles.

Purpose of Test Elemental analysis is useful for identifying contamination, confirming additive content, and indicating system wear. The following elements are analyzed: Iron, Chromium, Aluminum, Lead, Tin, Copper, Silver, Nickel, Sodium, Vanadium, Titanium, Molybdenum, Calcium, Barium, Phosphorus, Zinc, Boron, Potassium, Magnesium and Silicon.

Test Description Particle count measurements are performed on a 10 mL oil sample, with results standardized to 1 mL. Samples must be homogenized and are then diluted 1:1 with a solvent mix (toluene and isopropanol) to ensure water and soft particles do not cause inaccuracies. The prepared sample is loaded into a syringe and passed through a laser sensor at a controlled flow rate, counting particles in different size ranges.

Purpose of Test Particle count is performed to detect and quantify contamination, ensuring the oil's cleanliness and the machinery's protection, thereby preventing wear and extending equipment life.

Purpose of Test Tracking the actual water quantity in a sample of in-service lubricant is crucial in identify the source of the water and noting changes in this contamination over time since water not only promotes component damage through pitting and corrosion, but lubricant breakdown through oxidation as well.

Purpose of Test AN of a used lubricant is one measure of its degree of degradation by oxidation.

Test Description BN is determined by titration with Hydrochloric acid (HCl) which neutralizes the basic compounds in the oil sample and then is converted to grams of potassium hydroxide (KOH).

Purpose of Test TBN of a used lubricant is a measurement of its ability to neutralize the acid commonly found in combustion engines.

Test Description The infrared absorption spectrum of a lubricant furnishes a means of fingerprinting organic compounds and functional groups. Test results are trended and qualitative determinations can be made.

Purpose of Test Infrared analysis is often used to identify trends in lubricant degradation due to oxidation or contamination such as nitration or water.

Test Description A visual inspection of the oil is performed upon arrival and a small amount of oil is placed on a hot plate heated to 265 °C which will indicate the presence of water with a crackling sound. Unfortunately, this test is imprecise and can be inaccurate which is why the Karl Fisher test for water is crucial to a well-maintained oil analysis program.

Purpose of Test This screening is used to provide a description of any egregious issues with the sample.

Test Description A portion of the sample is heated to the correct temperature (40 or 100 °C) and pulled into a tube. The pressure is released allowing the lubricant to fall with gravity and the time is measured as the lubricant passes two specified points in the tube. The shorter the time, the lower the viscosity.

Purpose of Test The viscosity is the most important characteristic for oil. If the viscosity is too low, components will not have separation during operation and wear will be generated. If the viscosity is too high then the operating temperatures will be higher and the lifespan of the motor may be diminished.

Service Offerings

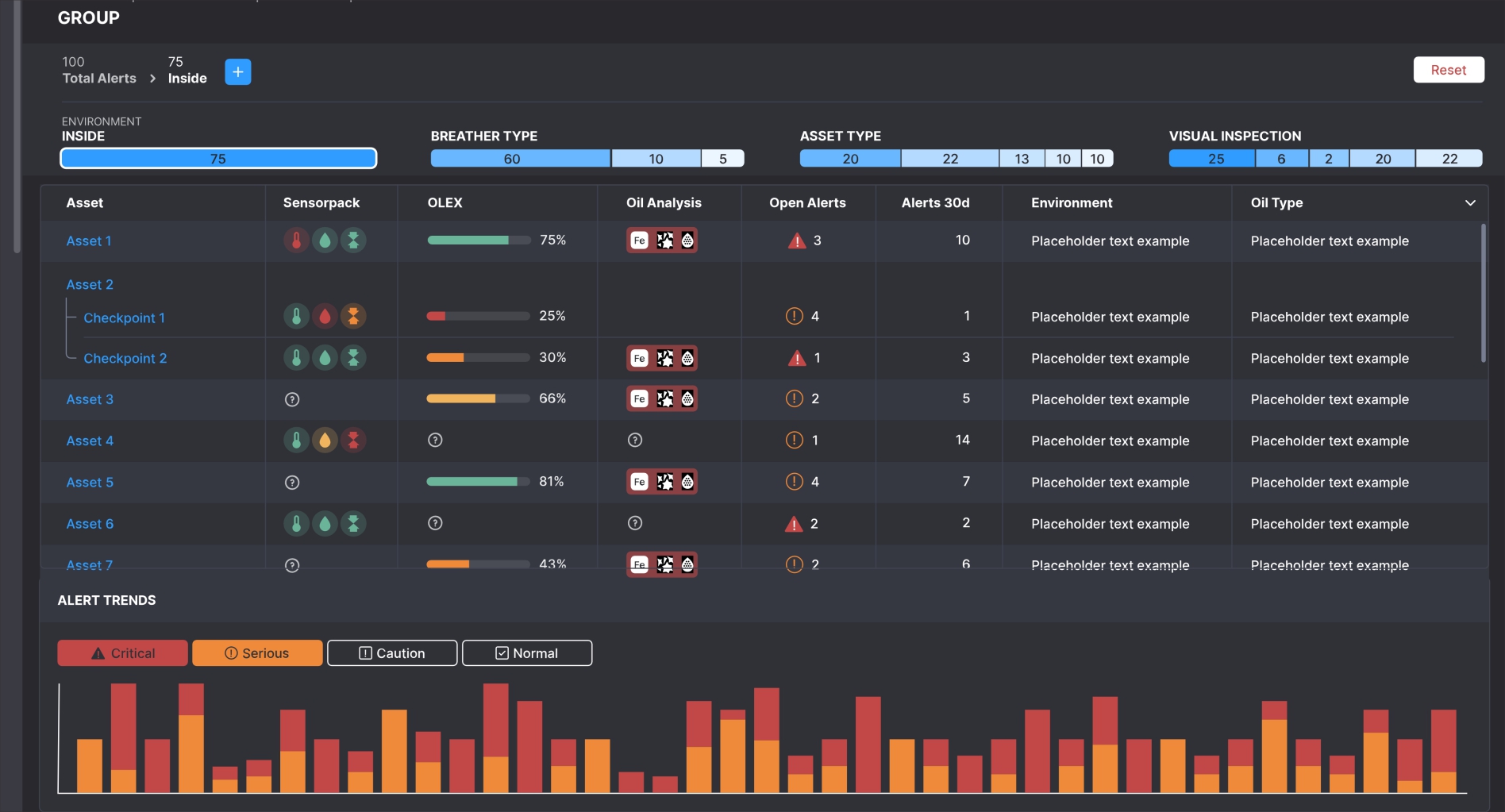

Sensei Platform. The Intelligence.

Your intuitive, web-based dashboard for monitoring and analyzing equipment and lubricant health from Sensei Devices on the network.

The Sensei Difference.

No more wondering. No more worrying. No more wasting time.

Powerful

Simple

Secure

Flexible

Monitor your equipment - Sensei style.

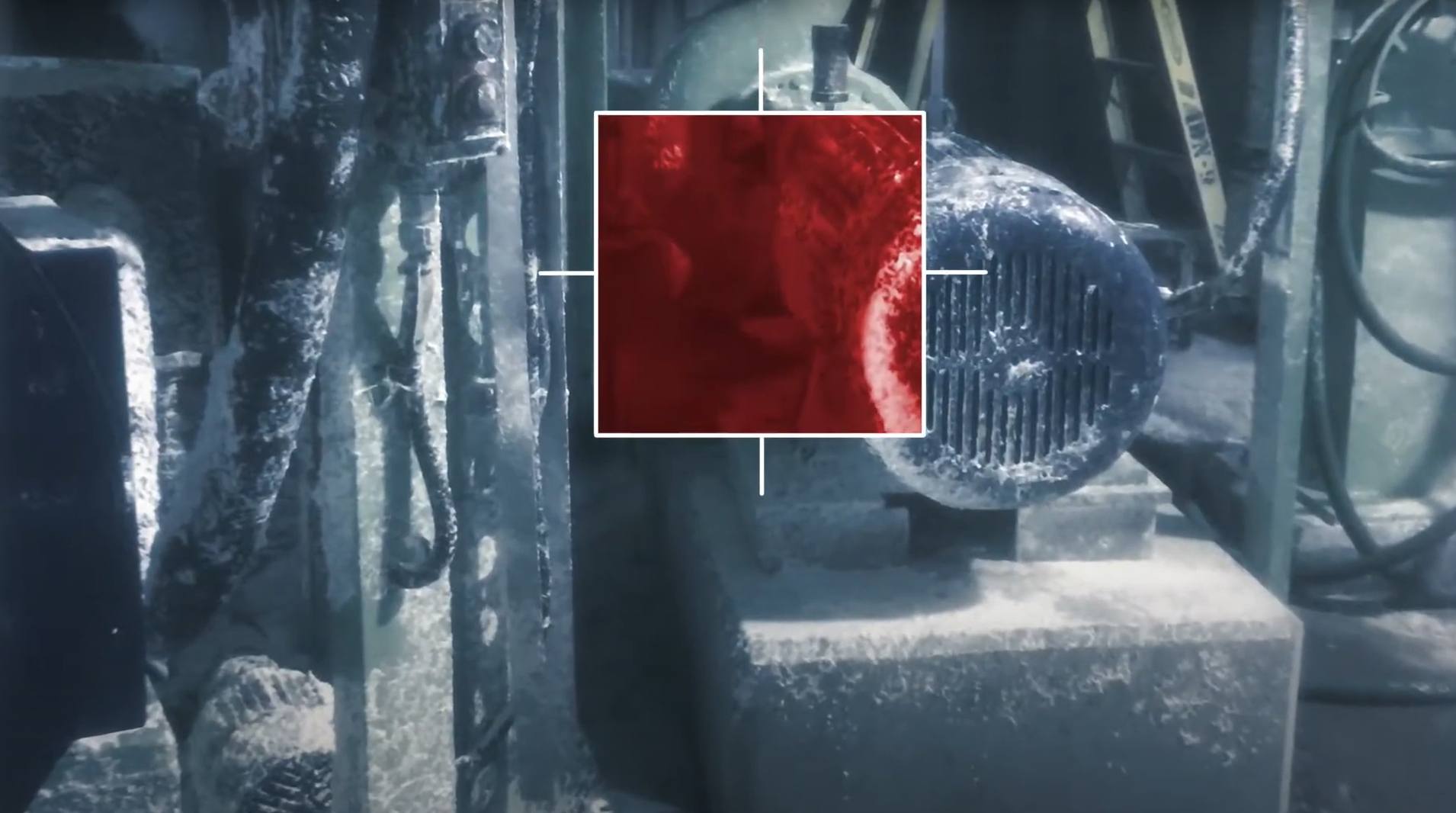

Sensei IIoT Network keeps you continuously informed about lubricant and equipment health - so you can stay ahead of potential problems, while avoiding unnecessary maintenance. It's an ideal opportunity for your plant to make more proactive, data-driven reliability decisions.

01 Improve Reliability

02 Increase Efficiency

03 Powerful Analytics

04 Simple Integration

Sensei

Sensei Platform enables proactive, data-driven equipment reliability decisions.

Explore Sensei

Sensei

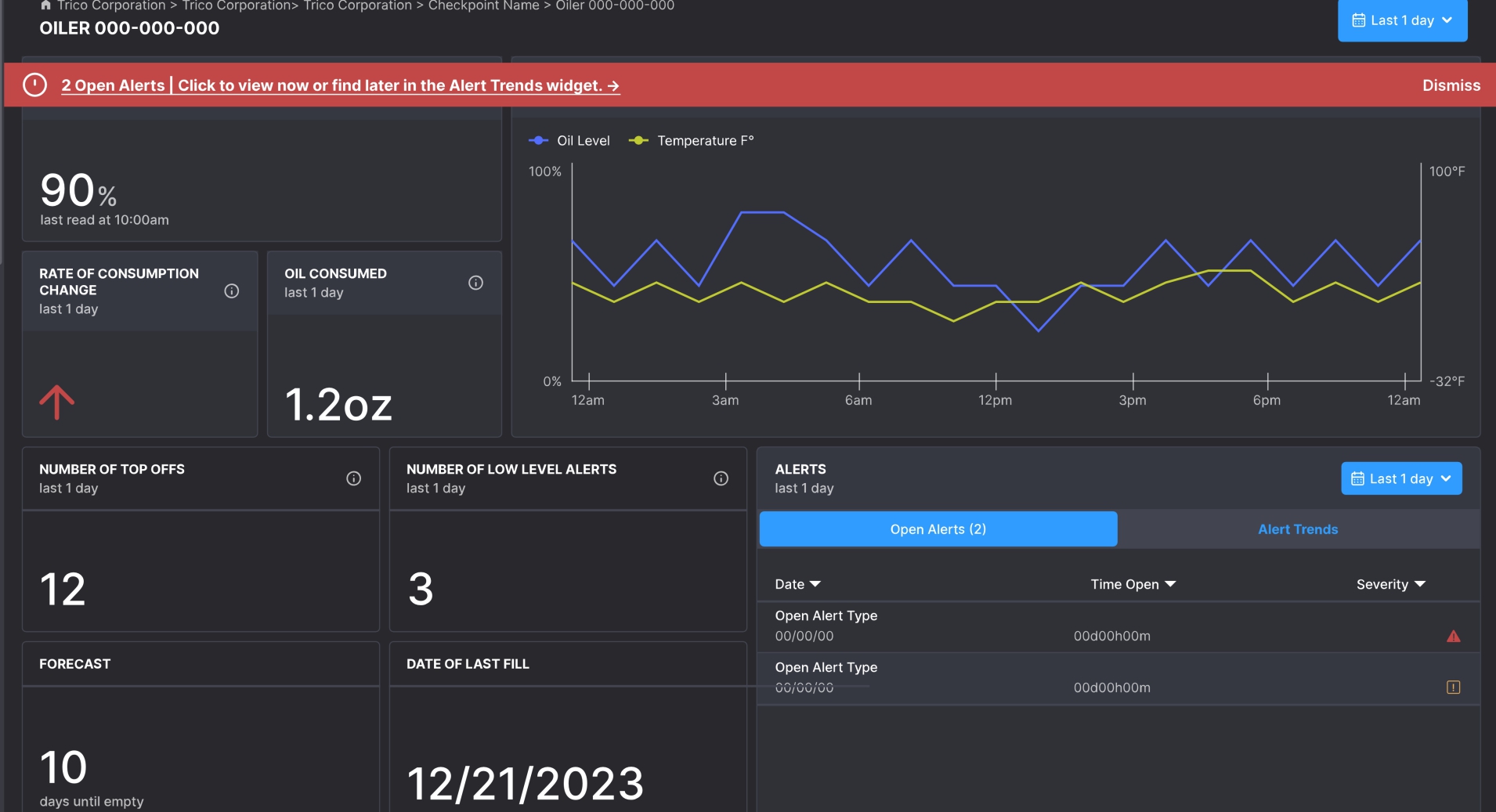

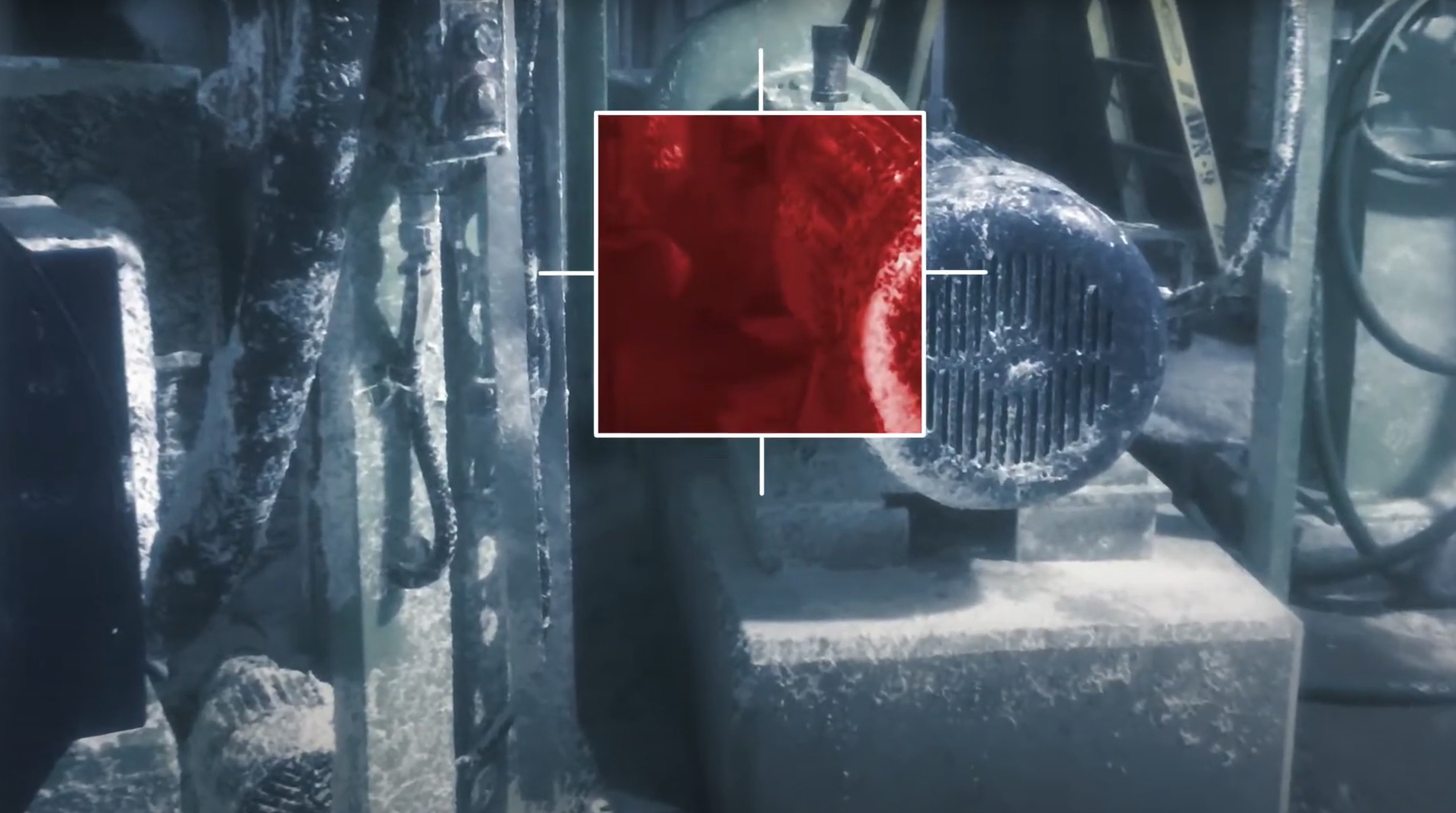

Seeing the Unseen

Get to Know Machine Vitals

Machine Vitals monitors temperature, relative humidity, pressure, and acoustics.

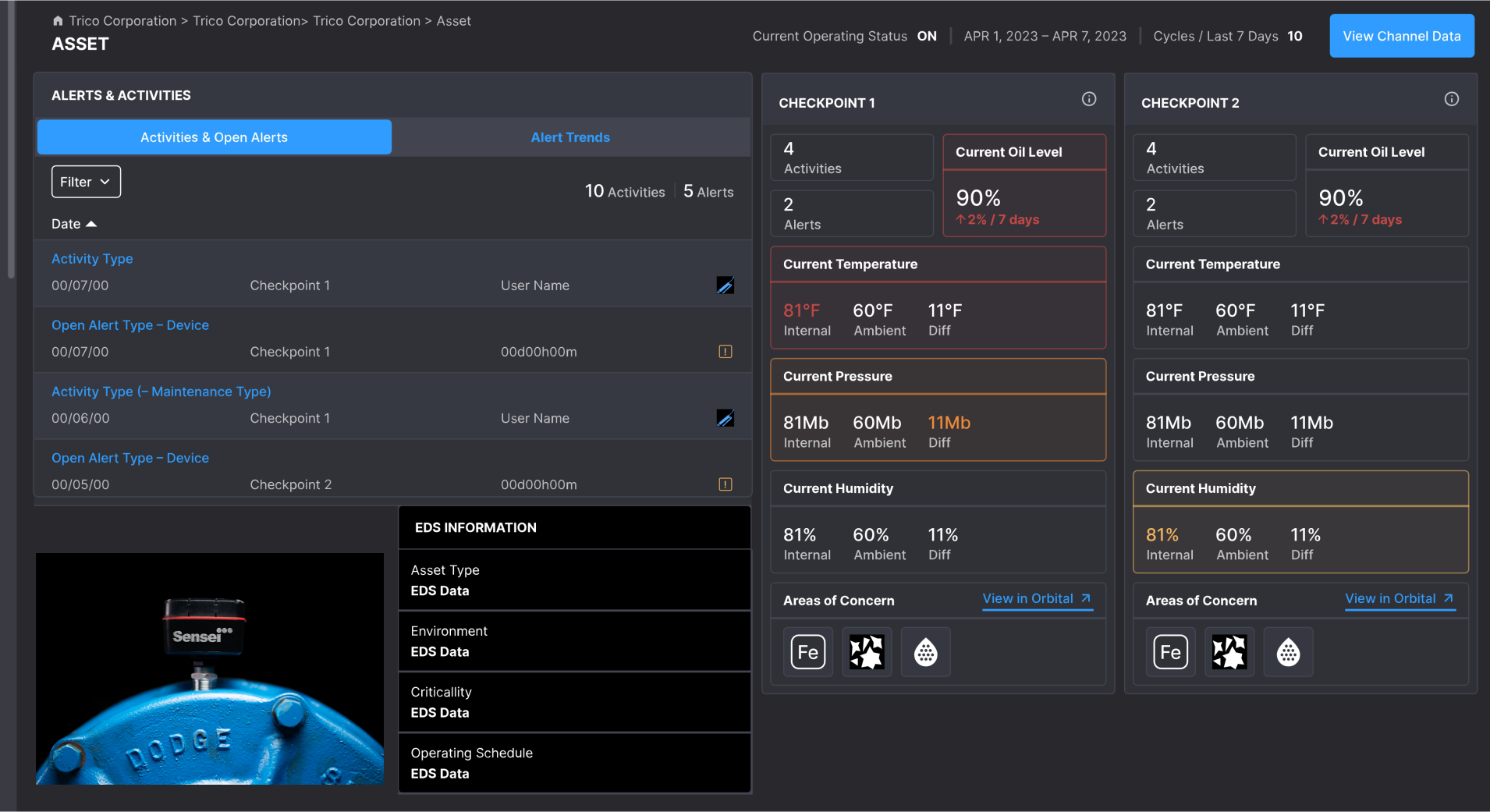

Why do you need Sensei Devices?

They are used to detect and prevent equipment failures by continuously monitoring and analyzing various parameters and performance data in real-time.

Improve Reliability

Stay informed instantly about any issues and preventing them from escalating into major problems.

Save Time

Access equipment data easily, eliminating the need for manual checks and saving valuable time for your team.

Gain Powerful Insights

Monitor key parameters 24/7 and utilize analytics to suggest preventive measures and drive performance enhancements.