.jpg)

Dan Freeland

01.17.2023

From Pilot to Implementation in Pulp and Paper

Just over 18 months ago Trico released our first generation of IIoT products into the market. Sensei Enabled Opto-Matic Oiler is a wireless industrial lubrication monitoring device designed to provide maintenance and reliability engineers with the ability to monitor the lubricant supply in their equipment from their PC or mobile device. The very real problem of understaffing and fire fighting constant issues have led to the fall off of routine inspections and lube route walk arounds. Not being able to physically monitor these lube levels usually only leads to more firefighting. Sensei Enabled Opto-Matic Oiler offers the opportunity to quickly check if a lubricant supply has been depleted in a specific piece of equipment. This can quickly be addressed without having to walk the entire route before finding an issue. This saves time and the potential for impending failures.

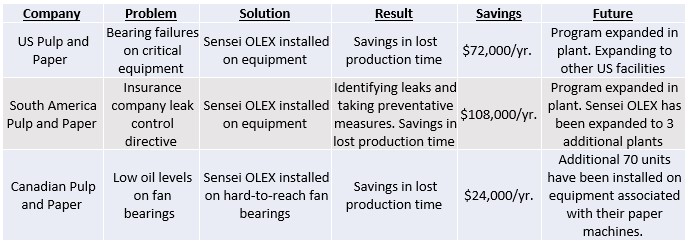

Sensei Pilots

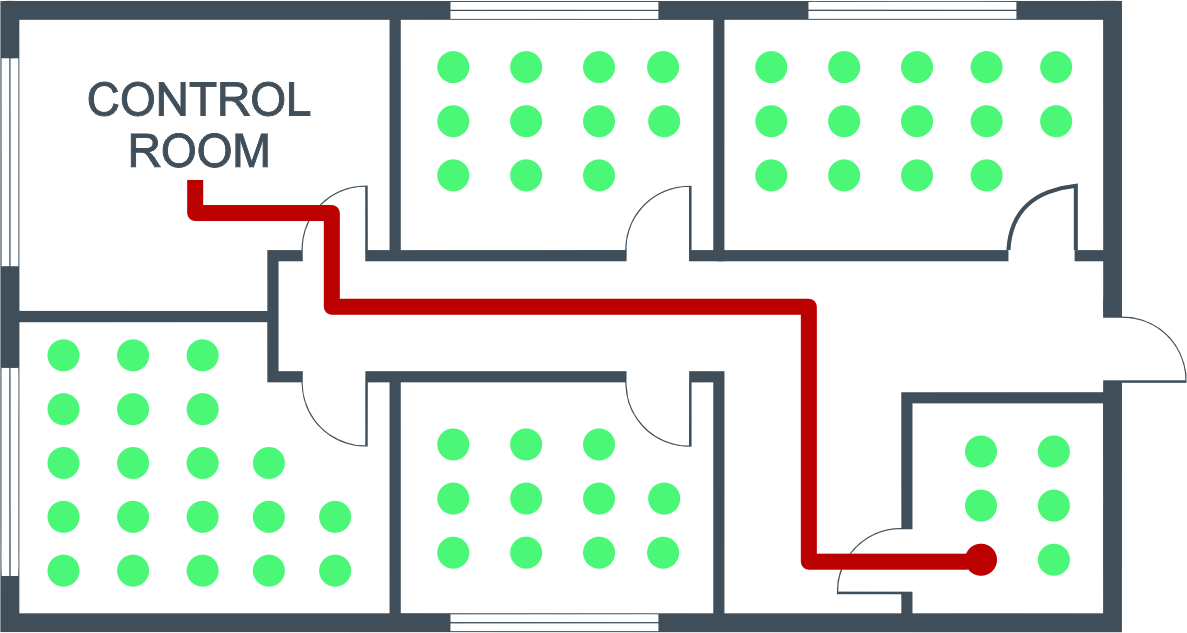

Recently, we have seen companies in the pulp and paper industry take interest. This interest usually starts with a pilot program. A pilot program usually consists of a couple dozen sensors deployed on select equipment throughout the plant. Usually critical equipment, difficult to reach equipment, and/or distance challenging equipment. The pilot program offers the end user the opportunity to “test drive” the Sensei platform with limited risk and cost. It is becoming evident that these pilot programs have been a great success. The benefits of Sensei Enabled Opto-Matic Oilers are quickly realized and the program is expanded in not only the pilot plant, but in additional sister plants throughout the US, Canada, and South America.

Start a Pilot Program

There are many exciting things happening with the Trico Sensei platform. The Sensei Enabled Opto-Matic Oiler is taking off and in 2023 we will be introducing new and cooperative devices that are Sensei compatible. Don’t miss your chance to set up a pilot program for Sensei Enabpled Opto-Matic Oiler and start saving time and money. Feel free to call us today and join the excitement!