Dan Freeland

08.31.2021

Efficient, Automatic Lubrication Systems – Central Lubrication

Central Lubrication has been around since the early 1900’s and still serves a great purpose in lubricating all kinds of machines around the world. There are many different types of central lube systems that deliver oil and grease to lubrication points on a machine. Some of these include single- and double-line parallel systems, progressive systems, and air over oil systems. Trico has offered several kinds of these systems since the 80’s, mainly for oil, including Single Line Resistance Systems and Positive Displacement Injection Systems. These are generally more common, more reliable, and easier to install than the previously mentioned systems. This article will break down the different Trico offerings.

Single Line Resistance Systems

The Single Line Resistance lube systems are used throughout industry where reliable oil lubrication is required. The basic principle of these systems is to use a pump to provide oil lubrication to multiple locations on a machine that may have different requirements of oil required. Meter units are installed at the end of each line, creating a resistance to flow, by orifice size, to apportion different volumes of oil to each lube point. Common applications include punch presses, milling machines, printing presses, injection molding machines, textile machinery, cnc’s, and more.

PM-10 & 20 Series Manual Cyclic Pumps

These single shot systems use a manually actuated pump for applications where infrequent lubrication is required, such as a punch press that is used intermittently.

PM series pumps are used in applications where a fixed output of lubricant is desired. With the PM-10 series, the leverage of the pump handle enables the unit to deliver a higher pressure than most models, providing the ability to lubricate points having some back pressure. With the PM-20 series, lubricant output takes place upon release of the handle using spring discharge to assure the correct amount of lubricant is applied.

- Low, cost simplified installation and operation

- Manual and spring discharge pumps

- Reservoir capacities 450 cc and 550 cc

- Application with less than 50 points

- Maximum pressure 200 PSI (10 Series)

- Maximum pressure 70 PSI (20 Series)

PE-10 &12 Series Automatic Cyclic Pumps

In heavy duty applications requiring a timed delivery of lubricant, the PE 10 and 12 series automatic cyclic pumps are used. These spring discharge piston pumps provide long life and trouble-free service. With variable lubricant outputs and a choice of cycle times, they offer excellent versatility in many applications. An adjustment screw with a calibrated rod simplifies setting the lubricant delivery output.

- Transparent 2-liter reservoir

- PE 12 Series provide with low level switch to signal when lubricant level is low

- Adjustable output range of 3 to 6 cc/cycle or 3 to 120 cc/hour

- Convenient drop-in filter in fill port

- Maximum pressure 40 PSI

PE-20, 22, & 24 Series Automatic Cyclic Pumps

These pumps are designed for automatic cyclic systems with fewer than 50 points. This series of pumps introduce analog adjustment knobs for convenience. The PE-20 series knob adjusts the interval time between lubrication cycles of up to 60 minutes while the output lube cycle is integral and chosen by model number. 6 and 15 cc/cycle outputs are available at the time of purchase.

The PE-22 Series is the same as the PE-20 Series but includes a pressure gauge for system pressure reading.

- Adjustable interval time between lubrication cycles of up to 60 minutes

- Heavy duty plastic reservoir simplifies oil level viewing

- Choice of 6 cc or 15 cc output/cycle

- Low level switch with alarm

- Pressure gauge (PE-22 Series)

- Maximum pressure 100 PSI

The PE-24 series is the most versatile of this group incorporating not only the interval time adjustment knob, but includes an adjustable output cycle time knob of 1-180 seconds at a flow rate of 200 cc/min.

- Adjustable interval time between lubrication cycles of up to 180 minutes

- Heavy duty plastic reservoir simplifies oil level viewing

- Adjustable output cycle time of 1-180 seconds, flow rate of 200 cc/min

- Low level switch with alarm

- Pressure gauge

- Maximum pressure 70 PSI

PE-30 & PE-32 Series Automatic Cyclic Pumps

The PE-30 & PE-32 series are the most versatile automatic cyclic pumps available. Both the lubricant dispensing time, and the time interval between cycles is digitally controlled. With reservoir sizes up to 20 liters, these pumps can handle systems with up to 100 lubrication points.

PE-30 & PE-32 Series

- Low level switch with alarm

- Pressure gauge

- Heavy duty plastic reservoir (3 liter) simplifies oil level viewing

- Metal reservoirs available in 6, 8, and 20 liters for larger systems

PE-30 Series

- Adjustable output cycle time of 1-180 seconds, flow rate of 200 cc/min

- Adjustable interval time between lubrication cycles of 3-999 minutes

- Maximum pressure 100 PSI

PE-32 Series

- Adjustable output cycle time of 1-999 seconds, flow rate of 250 cc/min

- Adjustable interval time between lubrication cycles of 3-999 minutes

- Pressure adjustment valve

- Pressure switch, with reset button, shuts down pump if system pressure drops below set level, protecting against line or component failure

- Maximum pressure 140 PSI

PE-40 & PE-50 Series Continuous System Pumps

Trico’s continuous system pumps are designed for applications where lubrication of critical components is needed on a continual basis, rather than on a timed basis. Using continuous system control units, these pumps provide lubricant at flow rates of 250 cc/min and a maximum pressure of 140 PSI.

- Standard float switch provides signal when lubricant level is low

- Easy view plastic reservoir on 3 liter models, steel reservoir with sight ague in 6, 8, and 20 liter models

- Return to tank port available on 6, 8, and 20 liter models for returning unused oil to reservoir

- Provided with pressure gauge as standard

- Safety relief valve assures reliable performance

- Pressure switch, with reset button, shuts down pump if system pressure drops below set level, protecting against line or component failure (PE-40 Series only)

Meter Units and Control Units

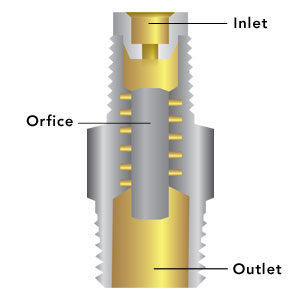

Meter units are used with all cyclic system electric and manual pumps to provide precise control of the lubricant to each lubrication point. A spring-loaded check valve keeps air from entering the system when lubricant is not being supplied to the meter unit.

Control units are used with all continuous system electric pumps to provide precise control of the lubricant to each lubrication point. Because pump flow is continuous, an internal check valve is not required.

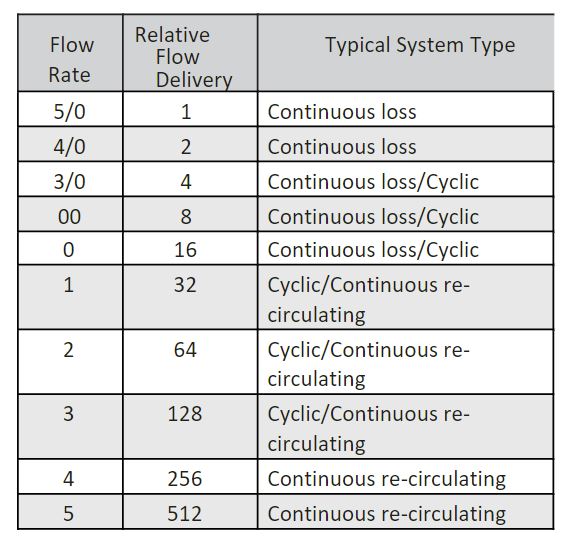

Industry offers 8 different flow rates for meter units (3/0–5) and 10 for control units (5/0–5). These units are precisely manufactured to accurately apportion oil at each point. Shown here is a chart that displays recommended flow rates for different types of systems. The relative flow delivery indicates the difference in the flow rates of the meter and control rates. The smallest flow rate is “5/0” and the highest flow rate is “5”. Each meter and control unit will allow approximately twice as much flow as the next smaller size, within a lubrication system. Actual flow rate is determined by pump discharge rate, number of lubrication points, and the other meter/control units in the same system.

Positive Displacement Injection System

Trico offers a line of products that complement the single line resistance systems. Instead of using meter and control units, a piston dispenses a pre-set amount of oil at each cycle of the pump. These systems do require that different pumps be used than a single line resistance system. All fittings and tubing are interchangeable between the two systems.

PE-34 & PE-44 Pumps for PDI Systems

The pistons used are called Positive Displacement Injectors. Positive Displacement Injectors (PDI’s) are an excellent means of providing lubricant to machinery. Using a piston principle, the PDI will lubricate individual points with specific amounts of oil. There are 6 output sizes to choose from: 0.06, 0.10, 0.16, 0.20, 0.30, and 0.50 cc’s per cycle. A typical system will include a pump, any number of PDI’s, and the necessary tubing and fittings.

At the start of the lubrication cycle, the PE-34 or PE-44 Series pump builds pressure. Upon pressure build-up, the PDI’s deliver the pre-set amount of oil. At the end of the lubrication cycle, a pressure unloading valve opens to return line pressure to 0 PSI. This allows the PDI’s to reset for the next cycle.

- Adjustable output cycle time of 1-999 seconds (PE-34 Series)

- Adjustable interval time between lubrication cycles of 1-999 minutes (PE-34 Series)

- Flow rate of 100 cc/min

- PE-44 Series is specifically designed for use with external user installed controls

- Maximum pressure 200 PSI

Getting Started

Hopefully, this overview of our central lubrication line of products is enough to get you started in selecting a pump and components for your next central lube project. System design can be a bit complicated. Feel free to visit tricocorp.com to download a design guide or give us a call and we can assist you with your application.

Learn more about the central lubrication line of products by watching this video.

- Category:

- Application

- Tags:

- Central Lubrication