Jim Jung

03.10.2020

Drop the Drop Tube. Drain the Drain Sample. There’s a Better Way to Set Yourself up for Accurate, Insightful Oil Analysis Results.

You ever hear the saying, “Garbage in, garbage out”?

Basically, it’s the idea that you can have a perfect formula, but if what goes into the formula is bad, then the output will be bad, too.

Oil analysis is a great example. Poor planning and execution while taking the oil samples for analysis will lead to inaccurate or irrelevant oil analysis reports, and incorrect or even harmful responses.

There are a lot of suspect oil sampling methods out there. Here’s one – sticking a drop tube in a wide-open reservoir:

See anything of concern here?

Contamination risks?

Safety issues?

Could you take a consistent sample this way?

You can do better – and when you do, you’ll get more accurate insights about your equipment that you can actually use to improve reliability.

Let’s take a quick look some at oil sampling best practices and evaluate the typical methods.

Your Basic Best Practices

- Flush sampling valves and sampling hardware, and keep the bottles clean. This helps ensure you get fresh samples without cross-contamination from old oil.

- Sample from live zones of machines running at normal operating temperature, load, pressure and speed. This helps ensure the sample represents what’s actually happening in a machine, and any insoluble and semi-soluble dirt, water and other debris are suspended evenly.

- Label samples clearly and send to the lab immediately. For various reasons, many people wait before shipping samples to their lab. Don’t! The profile of the oil can change over time, so the longer you wait, the less the sample will reveal the truth of what’s happening.

- Sample from the same place in the same way every time for accurate comparisons.

While adhering to these best practices, which sampling method will lead to the most accurate and instructive oil analysis insights? Let’s compare four possible methods.

| Method | Pros | Cons |

| Drop Tube Sampling (egregious example pictured above) | Cost effective. | Exposes open system to environment.Difficult to ensure consistent location.Risk of tube getting caught in system while sampling. |

| Drop-Tube Vacuum Pump Sampling | Inexpensive.No installation required.Appropriate for drum sampling. | Must ensure pump is in good condition and not contaminated with oil, dirt, water, etc.Must use new tube each time. |

| Drain Sampling | Inexpensive.No installation required.Suitable for testing homogenous properties. | Typically not representative of live zone lubricant.Contaminants from the outside surface of the machine can compromise the sample’s accuracy. |

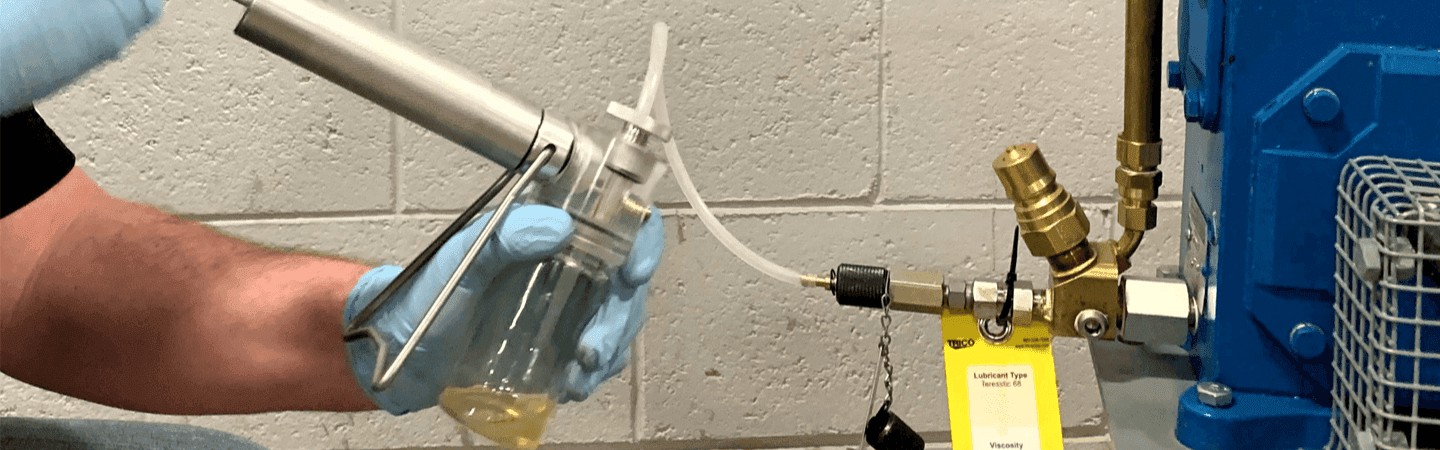

| Pitot Tube / Test Sample Port Sampling | Can be adapted to fit any configuration.No leakage – Normally closed valve and secondary leakage protection.Minimal flush volume.Can be used under high pressure. | Requires machine to be down for installation.Requires an adapter for extracting the sample.Requires knowledge of internal layout of equipment to hit turbulent zone. |

Despite the need for downtime installation, the clear winner is a permanently mounted Pitot tube or sample port. It’s ideal for reaching turbulent zones, it’s adaptable to many different application needs and it facilitates clean, consistent sampling methods.

You can view a variety of high-quality oil sampling components on Trico’s website. Of course, oil sampling needs vary by application and facility, and each method has its own set of appropriate practices. So, don’t hesitate to seek help from us to figure it all out.

Below, you can download and share an overview of sampling basics and recap of these tips.