.jpg)

Dan Freeland

12.06.2022

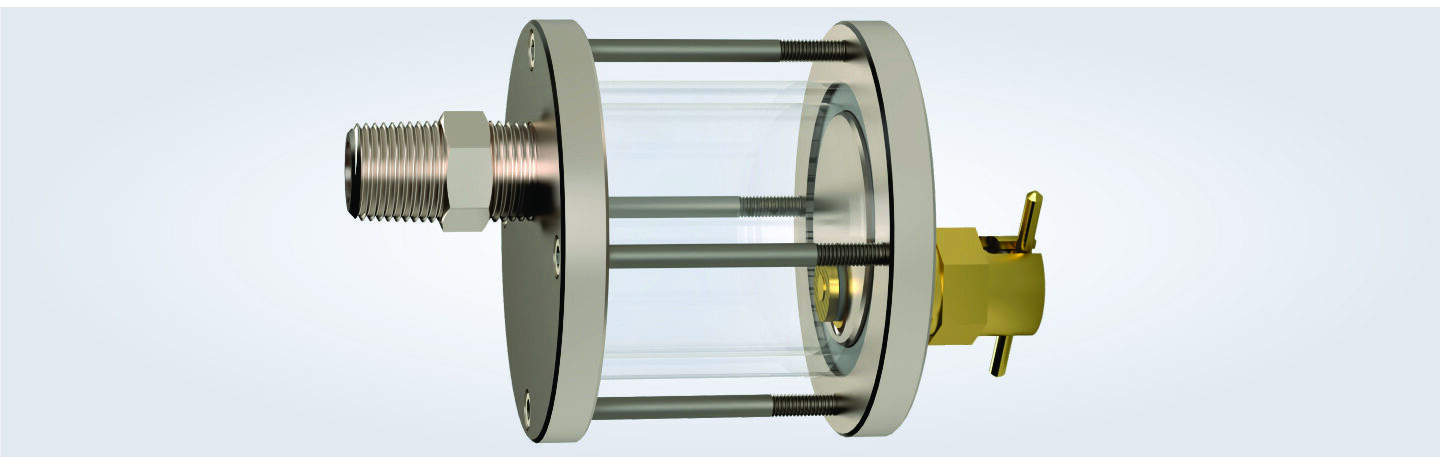

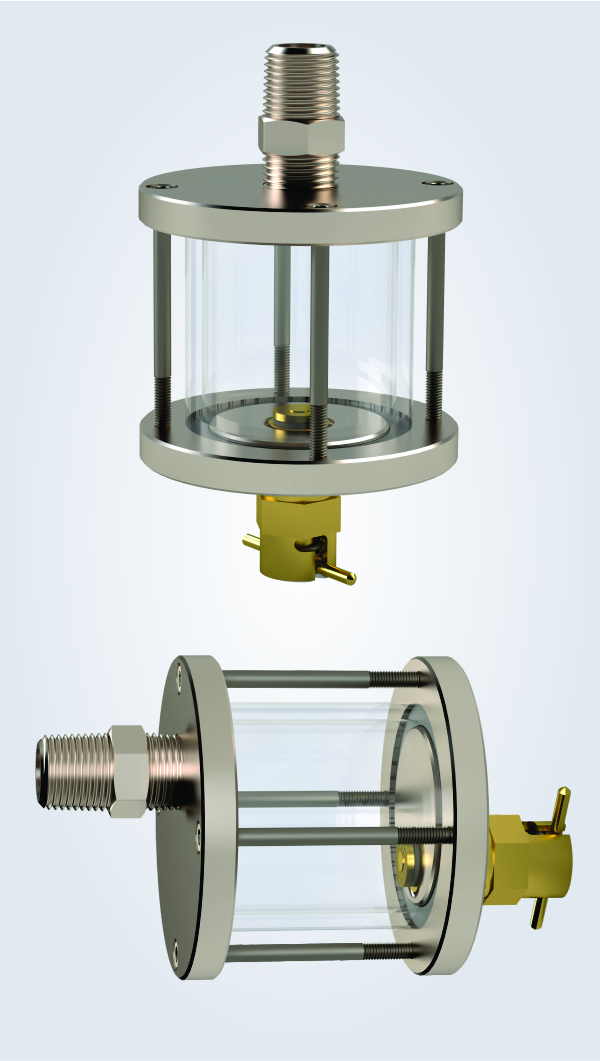

BS&W Bowls with Spring-Loaded Valve

Ba ck in April of 2021, we looked at the additions to the American Petroleum Institute’s (API) release of the API Standard 610 12th Edition: “Centrifugal Pumps for Petroleum, Petrochemical, and Natural Gas Industries”. One of the additions to the 12th edition was specifically targeting “Bottom Sediment and Water” Bowls.

ck in April of 2021, we looked at the additions to the American Petroleum Institute’s (API) release of the API Standard 610 12th Edition: “Centrifugal Pumps for Petroleum, Petrochemical, and Natural Gas Industries”. One of the additions to the 12th edition was specifically targeting “Bottom Sediment and Water” Bowls.This addition identifies using, if specified, an oil sump collection container. These have been around for many years in various configurations and names. Sump bottles and BS&W bowls are used to collect water and particulate at the bottom of a lubrication supply on equipment. Also included in this standard is the specification that the valve be a spring-loaded drain petcock. Trico has had sump bottles in their product offering for many years, but the release of this standard had us review our current products and implement some significant changes.

.jpg)

- Upgraded construction from crimp and epoxy to a mechanical bolt, gasket, and glass cylinder design.

- Upgraded materials from plated steel and plastic to stainless steel, brass valve, and glass.

- Upgraded from the screw plug and ball valve to the newly specified spring-loaded drain petcock.

- Added the option for volume of 2oz. or 5 oz.

- Added an offset horizonal application.

These well-appointed changes have made the product more robust and therefore more reliable. The additional options have opened the door to many more applications. The operating temperature rating has risen from 165°F to 225°F continuous use. The materials selected are sufficient for most industrial applications, and the spring-loaded valve prevents the susceptibility to leaving a ball valve open or a leaking plug.

If you are in the market for a sump bottle or BS&W bowl, its time you check out the new API Sump Bottles from Trico. You won’t be disappointed.

- Category:

- Application