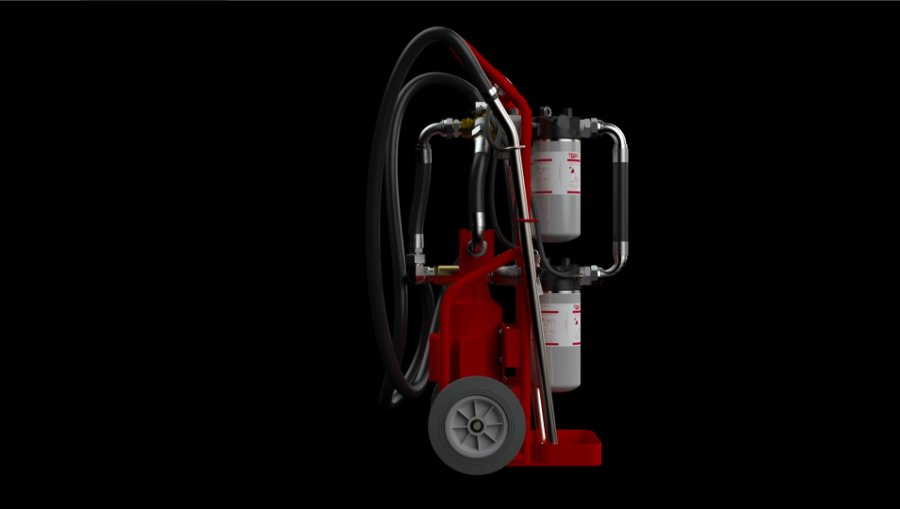

High-Viscosity Filter Cart System

This system is specifically designed for high-viscosity fluids associated mainly with gear oils and can filter oils up to 7500 SUS @ 100ºF (1600 cSt @ 40ºC), up to and including ISO 680 gear oils. The problem with attempting to filter a high-viscosity oil with a lower-viscosity system is that the pump and filters are not designed to work with higher pressures required to push high-viscosity fluids through the system. As a result, these low-viscosity units operate primarily in “bypass” mode where little if any of the high-viscosity oil gets filtered.

Feature

Bypass Valve

Feature

FRL Filter (Pneumatic Only)

Feature

Differential Pressure Gauges

Additional Features

- Industrial Strength Tires

- Wide, solid tires capable of getting over large grate gaps

- Oil Sampling Ports

- Three sampling ports available to monitor condition of oil

- Heavy-Duty Cart

- Rugged and built to last

- Hose Assembly

- Heavy-duty hydraulic hose (6' or 10' lengths) with 3' long metal wands or quick connects

- Drip Pan

- Keeps work area safe and clean

- Quad Filters

- To ensure equipment receives the cleanest oil possible and for increased equipment life, the High-Viscosity Filter Cart System provides quad filtration. The oil flows through the primary filters first, where coarse particulate is removed. Then the fluid flows through the secondary filters where fine particulate and water are removed.

Other Specs

| Model | Description | Motor Type | Hose Length | Wands/Quick Connect Couplers |

|---|---|---|---|---|

| 36933 | Pneumatic High-Viscosity Filtration Cart | Pneumatic | 6' | 3-foot Wands |

| 36933-QC | Pneumatic High-Viscosity Filtration Cart | Pneumatic | 6' | 3/4" ISO B Quick Connect Couplers |

| 36933-QC-10 | Pneumatic High-Viscosity Filtration Cart | Pneumatic | 10' | 3/4" ISO B Quick Connect Couplers |

| 36933-W-10 | Pneumatic High-Viscosity Filtration Cart | Pneumatic | 10' | 3-foot Wands |

| 36970 | High-Viscosity Filtration Cart | 120 V, 60 Hz | 6' | 3-foot Wands |

| 36970-QC | High-Viscosity Filtration Cart | 120 V, 60 Hz | 6' | 3/4" ISO B Quick Connect Couplers |

| 36970-QC-10 | High-Viscosity Filtration Cart | 120 V, 60 Hz | 10' | 3/4" ISO B Quick Connect Couplers |

| 36970-W-10 | High-Viscosity Filtration Cart | 120 V, 60 Hz | 10' | 3-foot Wands |

| 36998 | High-Viscosity Filtration Cart | 220 V, 50 Hz | 6' | 3-foot Wands |

| 36998-QC | High-Viscosity Filtration Cart | 220 V, 50 Hz | 6' | 3/4" ISO B Quick Connect Couplers |

| 36998-QC-10 | High-Viscosity Filtration Cart | 220 V, 50 Hz | 10' | 3/4" ISO B Quick Connect Couplers |

| 36998-W-10 | High-Viscosity Filtration Cart | 220 V, 50 Hz | 10' | 3-foot Wands |

-

Pump TypeIndustrial Grade Gear Pump

-

Motor TypeElectric or Pneumatic

-

Flow Capacity4 GPM – Electric #36970

3.5 GPM – Electric #36998

3.0 GPM – Pneumatic #36933 -

Pump Speed1 -1/2 HP @ 1750 RPM – Electric #36970

1-1/2 HP @ 1425 RPM – Electric #36998

Max 4 HP @ 3000 RPM Variable – Pneumatic #36933 -

Maximum Inlet Vacuum8″ of Mercury

-

Hose Sizing1″ Suction and Discharge Line @ 6′ or 10' Long

-

Max. Operating Temperature200ºF (93ºC)

-

Pump By-Pass105 PSI

-

Filter By-Pass43 PSI

-

Maximum Viscosity1600 cSt @ 40ºF / 7500 SUS

-

Seal and Gasket MaterialViton®

-

Electrical Service Required120 V, 60 Hz or 220 V, 50 Hz (electric version only)

-

Air Inlet Connection1/4″ NPT Female (pneumatic version only)

-

Max. Operating Pressure100 PSI (pneumatic version only)

-

Weight140 lbs – Electric

156 lbs – Pneumatic -

Dimensions20.96"W x 23.82"D x 45.42"H

Precision Monitoring for Timely Filtration

Enhancing Filter Cart Efficiency

Incorporating Machine VitalsTM, part of the Sensei® IIoT Network, with your Filter Carts offers a transformative approach to monitoring and maintaining fluid cleanliness. By tracking changes in key parameters such as relative humidity, temperature, and pressure, Machine Vitals provides precise indicators of when your equipment requires filtering. This not only ensures that filtration is performed at the most opportune moments but also maximizes the efficiency and lifespan of both the Filter Carts and the equipment they serve. As a result, you achieve a more proactive maintenance strategy, optimizing operational performance and preventing unscheduled downtime.

.jpg?width=1440&height=450&ext=.jpg)

.jpg?width=1444&height=454&ext=.jpg)