Oil Sample Ports

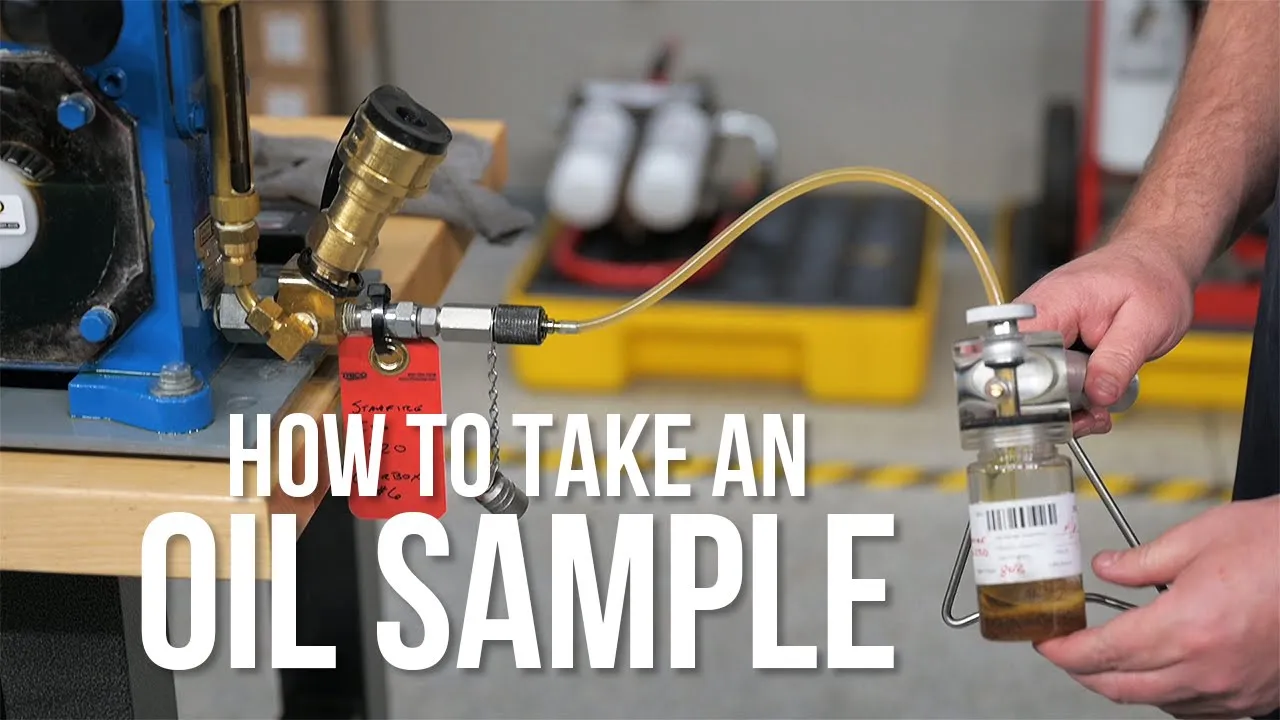

Where and how oil samples are collected are two of the most important functions of the oil sampling process. Without a representative sample, further oil analysis efforts will be ineffective. That’s why oil sample ports are designed to draw samples from the most representative areas of industrial equipment. Trico sample ports are also designed to collect samples under the equipment’s typical operating condition—another important factor.

Feature

Sample Extraction

The collection process is simple, fast ,and accurate way of sampling hydraulic, lubricating, and circulating systems. Access to systems is done through the use of a mating sample port adapter. The sample port adapter screws onto the sample port. Oil samples can then be drawn from the system and placed into a clean sampling bottle for analysis.

Note: Color on oil sample port must be the same as oil sample port adapter to extract a sample (ie. black to black (carbon steel), gold to silver (stainless steel)).

Feature

Protective Dust Cap

Additional Features

- Contamination Protection

- To guard against contaminating the sample and for superior leak protection, Oil Sample Ports all feature a check valve and Viton® O-ring protective seal cap.

- No Equipment Shutdown

- Sample directly from lubricating oil while equipment is running.

- Versatile

- Used in conjunction with proper accessories, sample ports are adaptable to pressure, static, and vacuum locations.

Other Specs

| Model | Description | Port Connection | Dim B | Material |

|---|---|---|---|---|

| 36100 | Sample Port | 1/8" NPT | M16 x 2 | Carbon Steel |

| 36101 | Sample Port | 1/4" NPT | M16 x 2 | Carbon Steel |

| 36102 | Sample Port | 1/8" NPT | M16 x 2 | Stainless Steel |

| 36103 | Sample Port | 1/4" NPT | M16 x 2 | Stainless Steel |

Smart Monitoring, Smarter Maintenance

Detecting Lubricant Degradation with Machine Vitals

Machine Vitals™ plays a crucial role in detecting potential lubricant degradation, providing early warnings that can prompt the need for oil analysis. As part of the Sensei® IIoT Network, this advanced condition monitoring device tracks essential parameters like temperature, pressure, relative humidity, acoustics, and acceleratory variance, delivering a comprehensive overview of your equipment’s health. When Machine Vitals™ identifies signs of lubricant degradation, it indicates the necessity of using sampling products to draw an oil sample from the equipment for thorough analysis, ensuring proactive maintenance and optimal machinery performance.