Dan Freeland

11.07.2023

Harnessing the Journey of the Lubricant® for Optimal Performance

Orbital, the new web-based platform by Trico, is a significant step forward in the oil analysis business. Launched at the end of 2021, the platform aligns with Trico's commitment to providing the highest quality products and services to their customers. Orbital not only delivers the insightful reports and expert commentary that customers have come to expect but also offers an array of additional benefits. Its holistic approach to lubrication programs ensures that users have a comprehensive understanding of their equipment's performance, leading to more informed decision-making and optimized operations.

Incorporating the Journey of the Lubricant

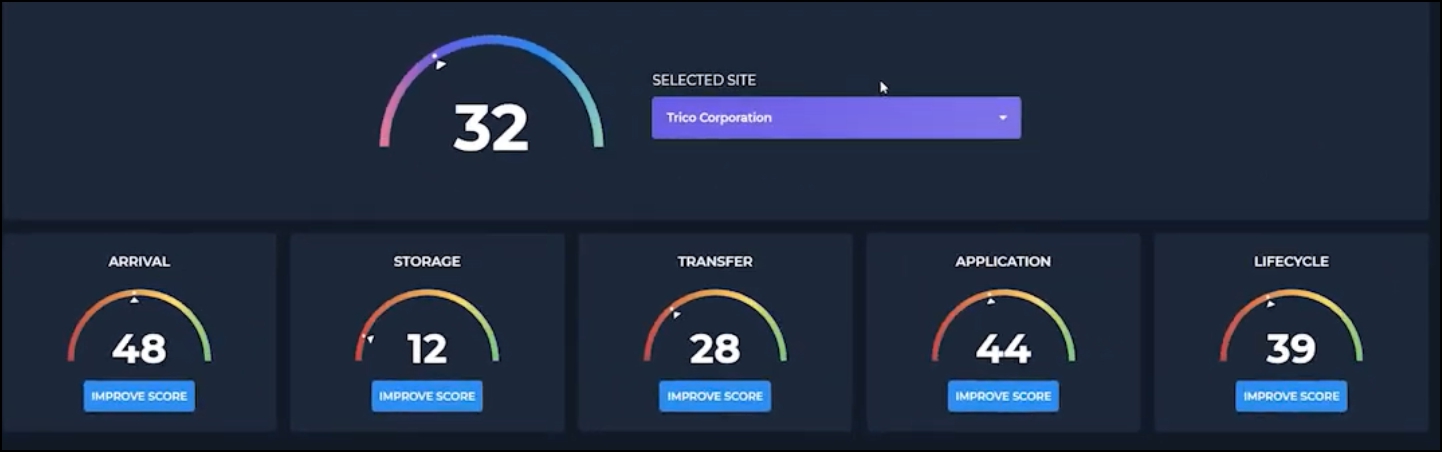

Orbital's transformative platform embodies a novel integration - the concept of the "Journey of the Lubricant". In doing so, Orbital introduces a unique feature dubbed the "Journey Score". The Journey Score offers a deep insight into your practices based on the oil sampling and information about the equipment itself, peripheral equipment, and surrounding environment, provided in your Equipment Data Sheet (EDS).The Journey Score comprises five distinctive stages that are part of the Journey of the Lubricant: Arrival, Storage, Transfer, Application, and Lifecycle. An Overall Score is also presented, which is an average of the scores obtained from the aforementioned stages.

The scoring methodology hinges on key factors such as:

- Fluid Quality: This pertains to the results of your oil analysis, which indicates the condition of your lubricant and its effectiveness according to the equipment's application requirements.

- Protection Practices: This factor evaluates the practices you have implemented to safeguard your lubricant from degradation.

- Contamination Ingression: This focuses on the methods used to protect your lubricant from water, particulate matter, and cross-contamination.

- Equipment Protection: This looks at the measures you have established to protect your equipment from environmental conditions, and the frequency at which you are performing oil analysis.

By offering a comprehensive scoring system based on these critical aspects, Orbital offers a program benchmark to start with. Continuously improving these at each individual stage, users can implement incremental changes that have a profound effect. The ripple effect of these changes can significantly improve the performance and longevity of your equipment, leading to enhanced operational efficiency.

Dimensional Oil Sampling Along the Journey

Dimensional oil sampling is the process of taking oil samples at each stage of the Journey. Each phase is critical to the lifecycle of the lubricant. Comparing these allows you to evaluate and identify the factors from an oil quality perspective that are most significantly impacting your program.- Arrival: Orbital provides an indication of the condition and care your supplier has taken to ensure the lubricant meets specifications and is contaminant-free.

- Storage: Identifies how your practices are impacting your lubricant condition.

- Transfer: Provides the best baseline for equipment test results. Any changes from storage to transfer are affected by personnel interactions.

- Application: In-use oil analysis offers the earliest warnings of wear and helps detect detrimental contamination.

- Lifecycle: Effective maintenance programs incorporate ongoing, routine oil analysis, and data trending for continuous improvements.

The strength of Orbital lies in its ability to allow users to compare, combine, analyze, and report on all data points integral to the health of their equipment and lubricant. This results in a far-reaching view of system performance that goes beyond traditional analysis, helping users to not only keep their operations running smoothly but also to preemptively identify and address issues before they escalate.

Results

With the wealth of data provided by dimensional oil analysis, equipment data, and effective correlation, Orbital offers a distinct advantage in the world of reliable maintenance and successful lubrication programs. Utilizing these powerful tools users are able to:- Increase Equipment Availability: With Orbital, you can quickly identify equipment that needs attention, allowing you to concentrate directly on resolving any issues.

- Uncover Bad Actors: The platform's deep data correlation can help you uncover trends, fine-tune equipment performance, and identify equipment that consistently underperforms.

- Anticipate Failures: More data means the ability to anticipate failure risks, empowering you to prevent problems before they occur.

- Trend Historical Data: Benchmark and track data to achieve real, lasting improvements that profoundly impact various aspects of your reliability program.

- Gain Control: Orbital gives you full control to easily update and add new equipment and lubricant information from the mobile app.

- Partner You Can Trust: You also gain access to our expert Oil Analysis Program Advisors, ready to clarify any questions you may have and provide advice on making your lubrication program a success.

It's not just about simple oil analysis, it's about harnessing the power of Oil Intelligence. Empowering users to dig into multiple data points, continuously cross-referencing and interpreting the relationships among them. It's through this intricate web of data and interpretation that users can uncover answers that directly impact their lubricants, their equipment, and their overall operation. Orbital invites you to stop the traditional practice of simple oil analysis and make the leap toward insightful Oil Intelligence.